Meet Dr. Evgeniya Pechnikova, our new Senior Applications Development Scientist

We are happy to announce that DENSsolutions has expanded the team with a wonderful new colleague – Dr. Evgeniya Pechnikova.

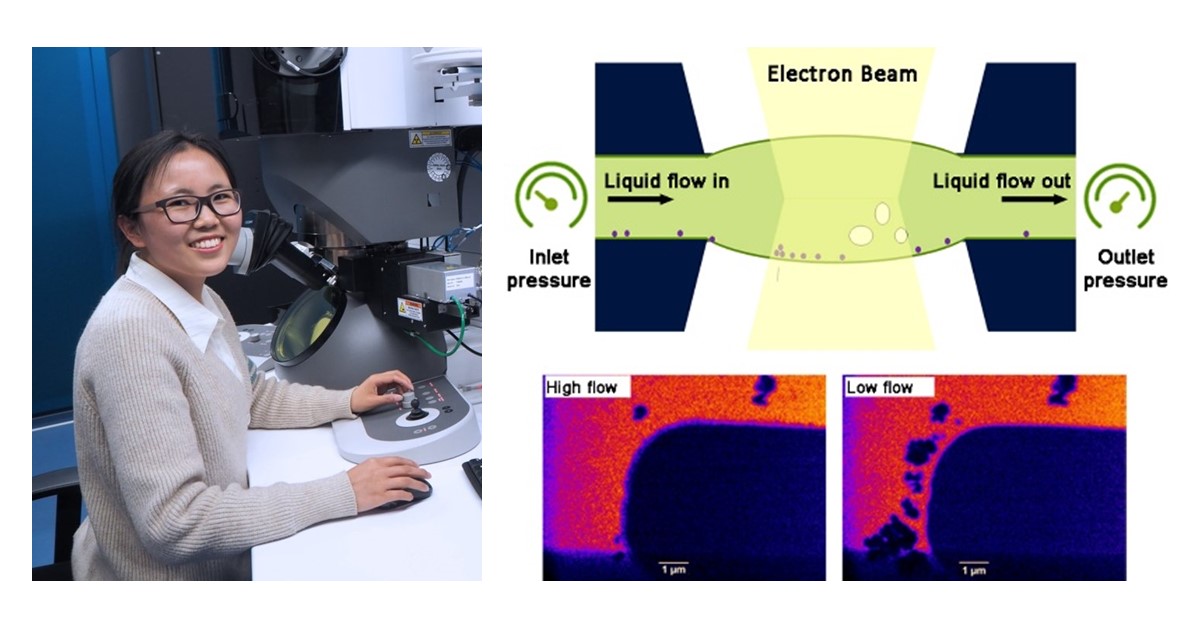

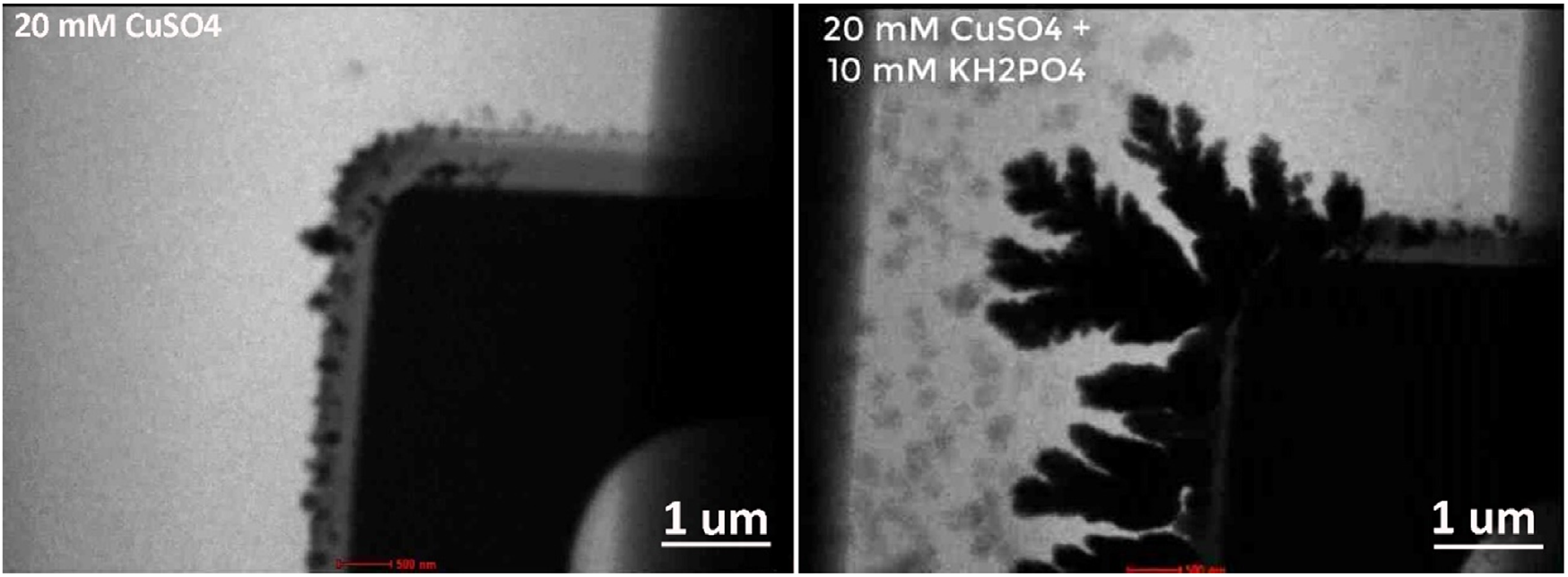

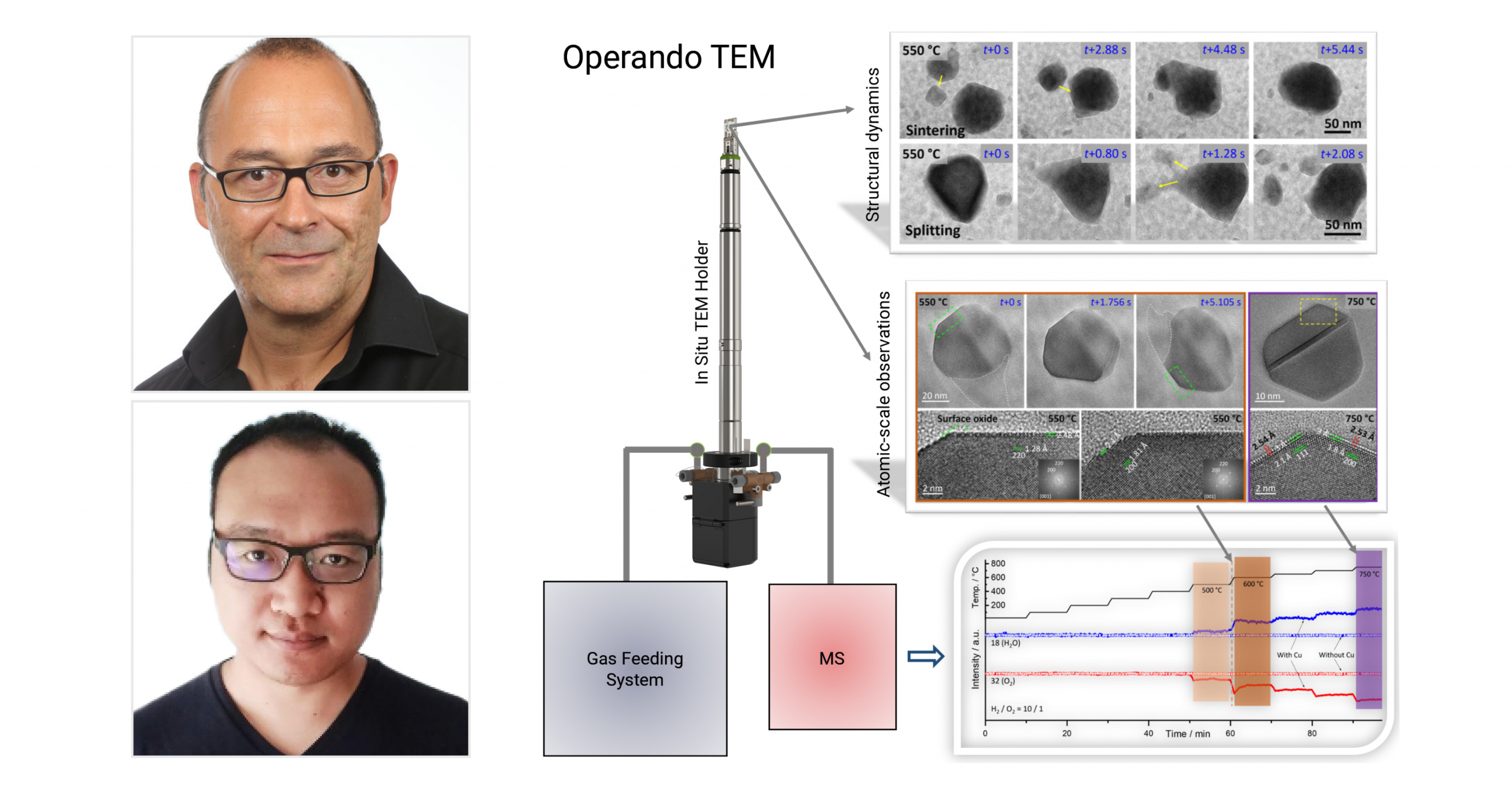

In the pursuit to grow our applications development for the DENSsolutions Stream system and other future product lines, we recently welcomed Dr. Evgeniya Pechnikova to the team – our new Senior Applications Development Scientist. Evgeniya has years of experience and high-level technical expertise in electron microscopy (EM), including cryogenic-EM, tomography and data processing techniques. Her role at DENSsolutions will be focused on developing novel in situ liquid EM applications that demonstrate the power of our solutions. She will also be working on creating new techniques and methodologies that will support the research of our customers, as well as perfecting our demonstration and installation protocols. We are thrilled to have Evgeniya join the DENSsolutions family and look forward to the valuable contributions she will make to the team on both a personal and professional level. In this article, we have asked Evgeniya to introduce herself so you can learn more about her extensive experience and her new role at DENSsolutions.

Meet Dr. Evgeniya Pechnikova

“My name is Evgeniya Pechnikova, and I was born and raised in Moscow, Russia. I have a lot of love for adventure and history, and enjoy travelling around the world to explore ruins of ancient civilizations. I’m also an avid fan of photography, Latin social dances like salsa and tango, as well as playing badminton and a game known as ‘werewolves’!

I have always been drawn to different spheres of science. That is why for my higher education, I decided to enrol in Lomonosov Moscow State University‘s biological faculty. As they had a very broad program there, I had the opportunity to learn about a wide range of subjects, starting with mathematics and physics and ending up with biochemistry, plant physiology and even drawing.

During my master’s degree, I was introduced to the world of electron microscopy and was completely fascinated by its combination of science and photography – two topics that have always been a passion of mine. To add another dimension to my work, I found a PhD position in the field of cryo-EM and 3D reconstruction, working on investigating the structure and function of capsids of a helical plant virus. My PhD project was a result of a collaboration between Lomonosov Moscow State University, Institute of Crystallography in Moscow and Birkbeck, University of London. During this PhD, I worked in close collaboration with structural biologists that were highly experienced in cryo-EM and image processing before the new detector technology popularised the technique to a broader base of scientists. This was an incredibly enriching experience and certainly shaped my career path moving forward.

After completing my PhD, I joined Thermo Fisher Scientific in the Netherlands where I worked as an Applications Scientist in the Eindhoven NanoPort facility – a state-of-the-art electron microscopy facility that provides users with hands-on experience with numerous analytical techniques. During this role, I was responsible for providing training and demonstrations for life science TEM equipment. I was also in frequent collaboration with the R&D department to translate customer needs into applications development, and to test new hardware and software tools. As a result of this work, I was able to play a role in accelerating the new-resolution revolution that has bloomed in cryo-EM over the past couple years. Importantly, this role made me realize that trying new tools to solve long-standing problems is what excites me most.

Now, as a Senior Applications Development Scientist at DENSsolutions, I have the unique opportunity to combine and explore two cutting-edge technologies, MEMS and cryo-EM. My top priority is to boost applications development and create working protocols that showcase the advantages of DENSsolutions’ MEMS technology within in situ liquid EM. I look forward to being actively involved in hands-on support during on-site and remote product demonstrations, as well as working with other departments to translate customer needs into workable solutions. I am excited to take on this new challenge and am confident that I will be able to make a meaningful contribution to the company, our customers and science as a whole.”

Get in touch with Evgeniya via: