Introducing Lightning Arctic: Our latest In Situ TEM Cooling, Biasing & Heating solution

An interview with DENSsolutions Senior Product Manager Dr. Gin Pivak about our latest addition to the Lightning product family: Lightning Arctic.

DENSsolutions introduces its latest product: Lightning Arctic – an innovative in situ solution that can perform cooling, biasing and heating all in one system. In this article, we interview our Senior Product Manager Dr. Gin Pivak to learn all about Lightning Arctic, including its unique capabilities and wide application space.

1) What are the main application fields that will benefit from Lightning Arctic?

“There are numerous applications where Lightning Arctic can play an important role. The ability to cool a sample and apply electrical stimuli enables researchers to study low-temperature physics, reaching temperatures as low as 100 Kelvin. It can be utilized to investigate magnetic materials and nanostructures, superconductors, topological insulators, ferroelectrics and more. Additionally, the application of Lightning Arctic can be expanded to include beam-sensitive materials such as Li-ion batteries, organic superconductors and perovskite-based solar cells, where the cooling capability can prolong the material’s lifespan under the electron beam. Furthermore, the ability to perform electro and/or thermal experiments at high temperatures allows the Lightning Arctic system to be used in the fields of nanomaterials sintering and growth, metals and alloys, low-dimensional materials, resistive switching, phase-change materials, solid oxide fuel cells, piezoelectrics, solid-state batteries and so on.”

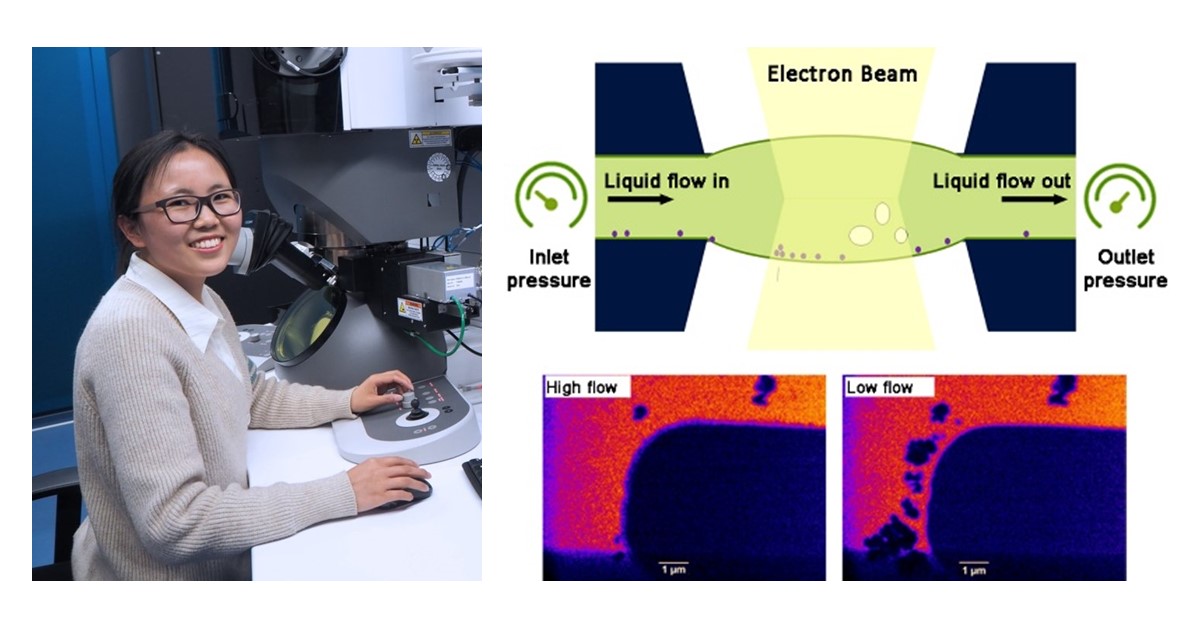

2) Has the system already been installed?

“Yes, the system has been installed at the Faculty of Engineering, Department of Materials at Imperial College London (ICL) in the UK. The main user of the Lightning Arctic system at ICL is Dr. Shelly Conroy, who is exploiting various ferroelectric and quantum materials at low temperatures and at atomic resolution.”

3) What are the main benefits of Lightning Arctic for users?

“Lightning Arctic brings forth numerous advantages for your in situ experiments:

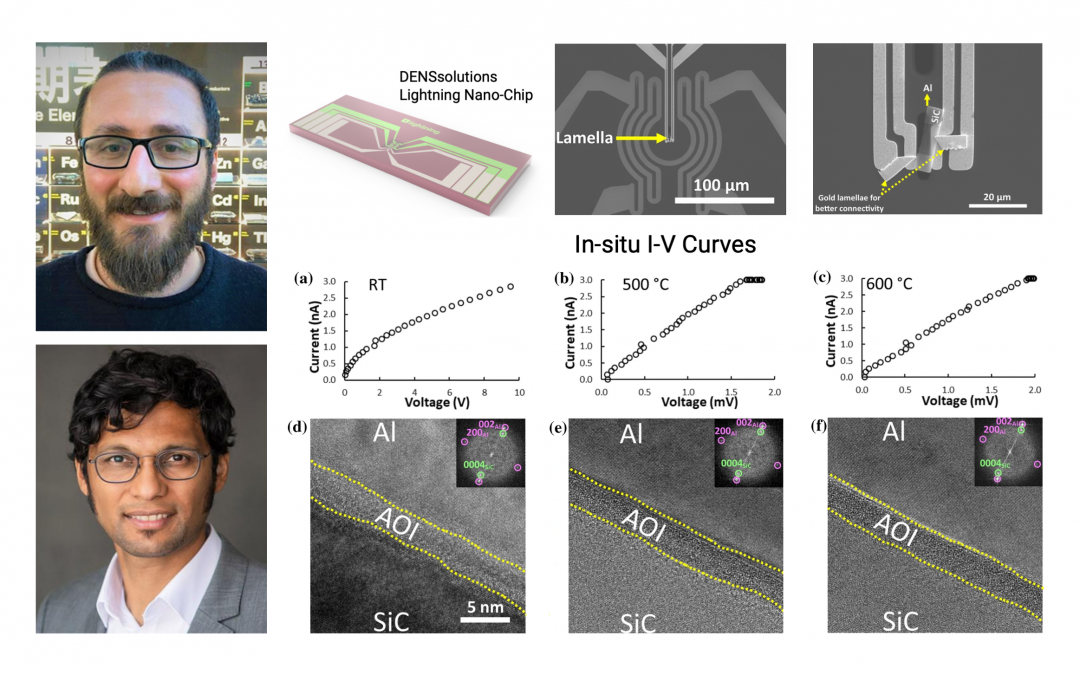

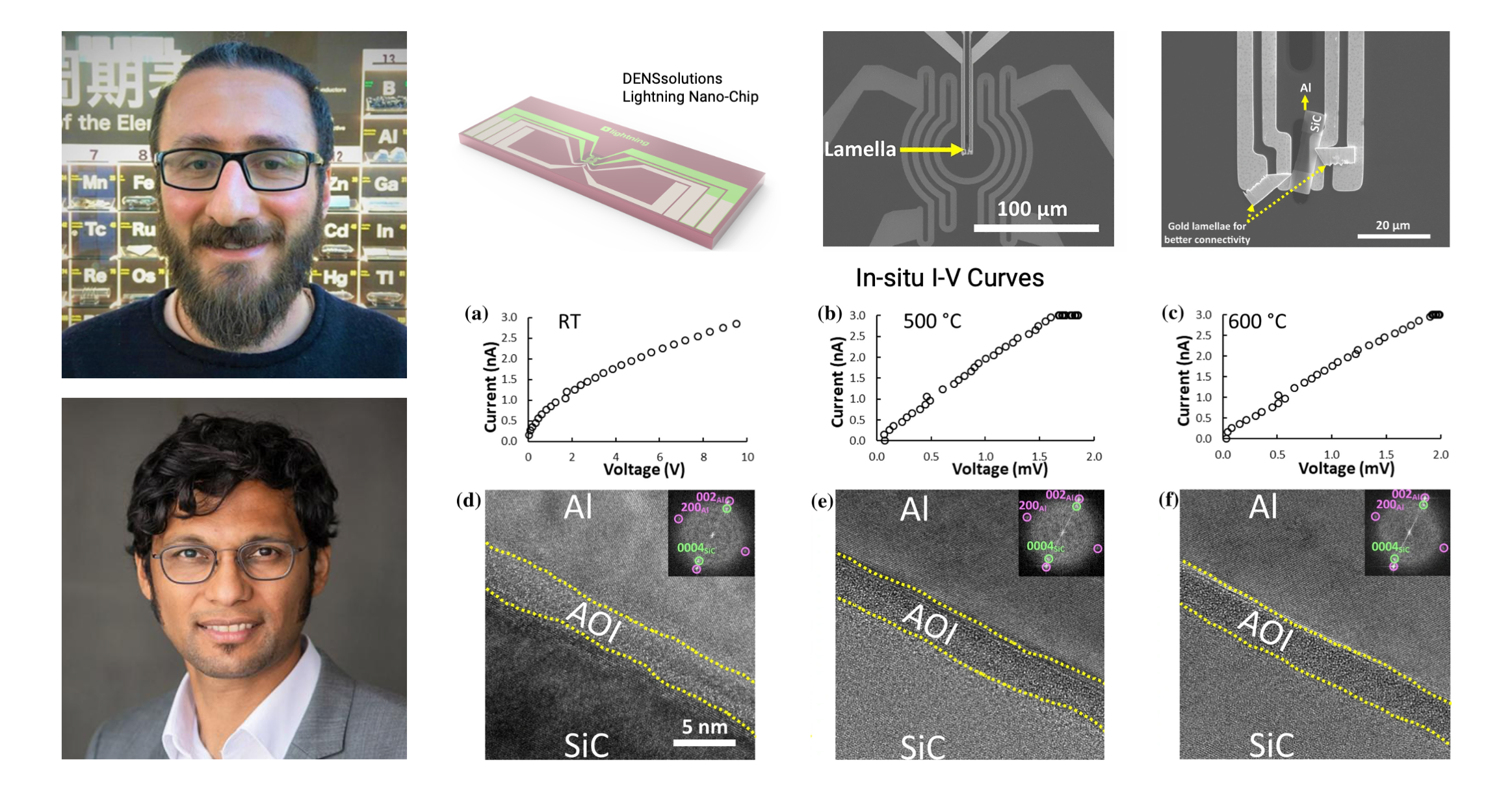

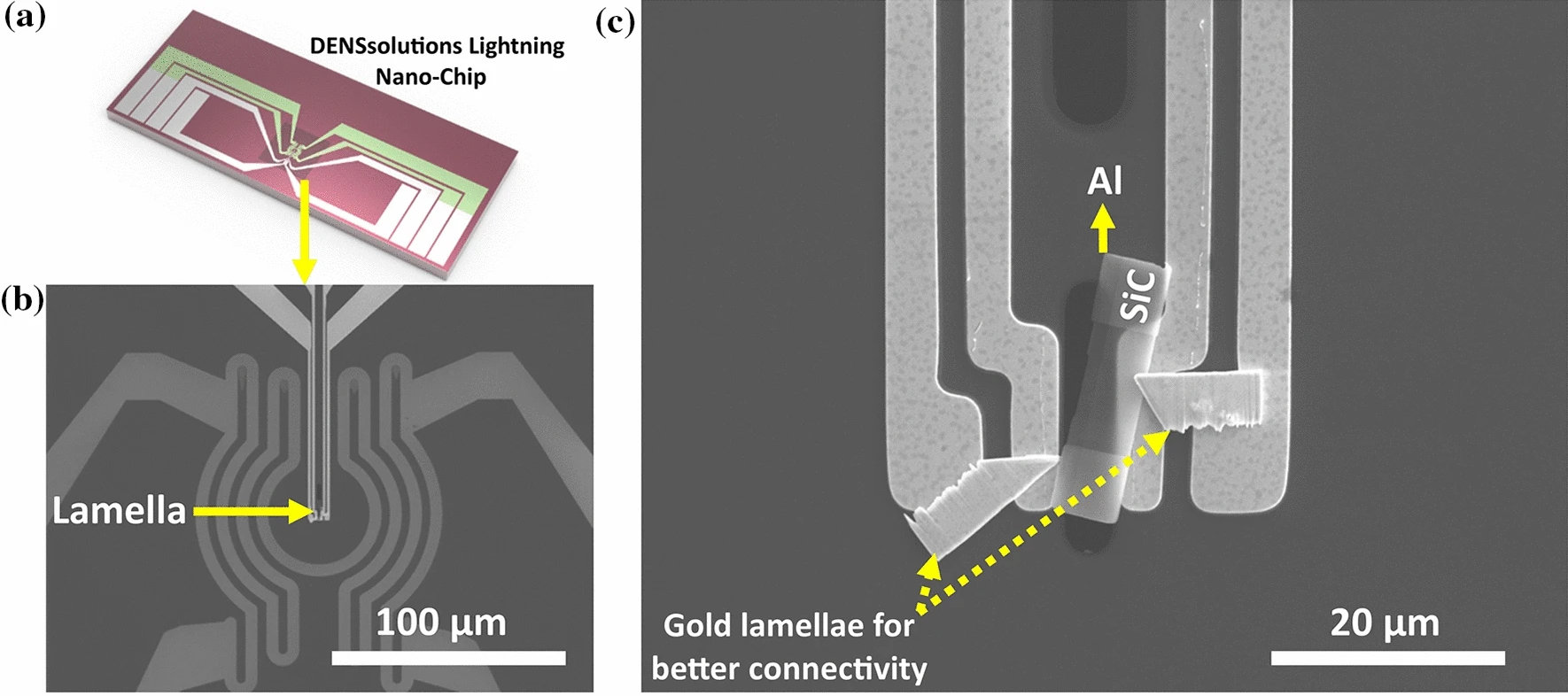

1) Perform in situ cooling and heating experiments: A cooling rod inside the Lightning Arctic holder can transfer the ‘cold’ towards the tip of the holder where the MEMS-based Nano-Chip holding the sample is located. Once this cooling rod is connected to a detachable metallic cooling braid which is immersed in an external dewar filled with liquid nitrogen, the sample can be cooled inside the TEM down to liquid nitrogen temperatures. Aside from cooling, the Lightning Arctic holder also enables in situ heating experiments, where the temperature can reach 800 °C and even 1300 °C depending on the chip used.

2) Experience atomic imaging stability: The Lightning Arctic holder was uniquely designed to host a number of additional temperature controllers that work to stabilize the sample drift during cooling. One controller ensures the temperature equilibrium with the TEM while the other stabilizes the cold influx towards the sample. The usage of the external dewar that helps to minimize the liquid nitrogen bubbling ensures that atomic imaging with low sample drift can be achieved.

3) Continuous temperature control: Our state-of-the-art Heating and Biasing Nano-Chips enable the local manipulation of the temperature of the sample while not disturbing the cooling process of the holder. This means that you can achieve the fast setting of any user-defined temperature and the minimization of the image and focus shift when changing the temperature setpoint, all while ensuring atomic-scale imaging quality.

4) Achieve your required sample orientation: The double tilt Lightning Arctic holder allows tilting the sample in both alpha and beta directions of 10 – 25 degrees to find the required zone axis of the sample.

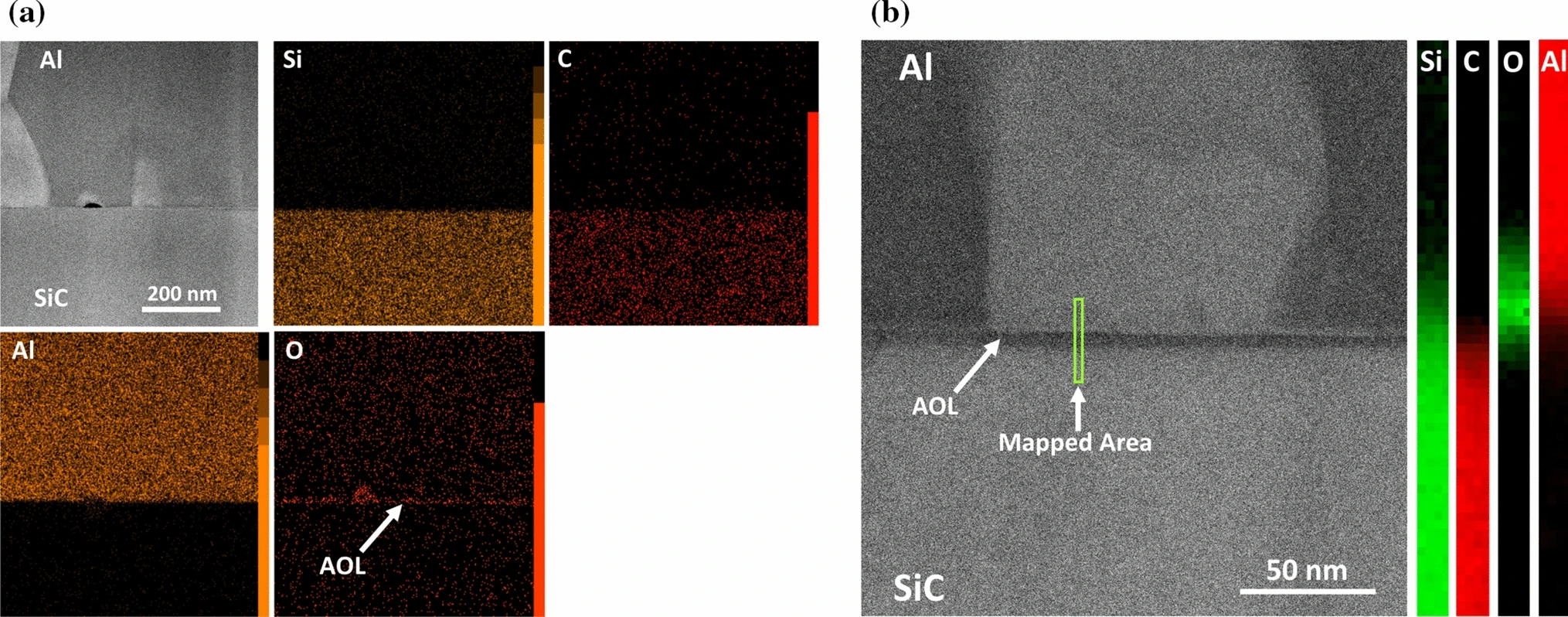

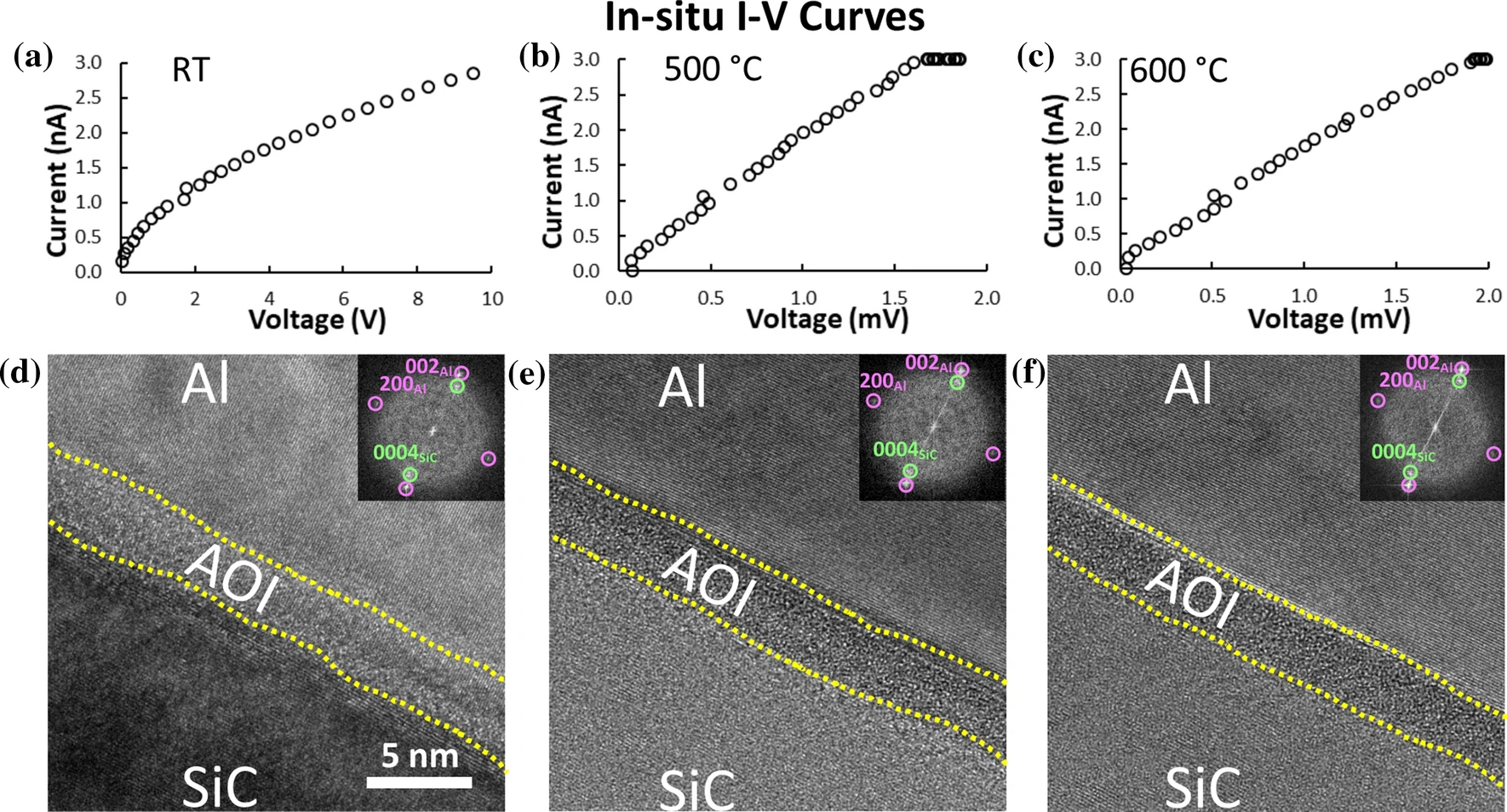

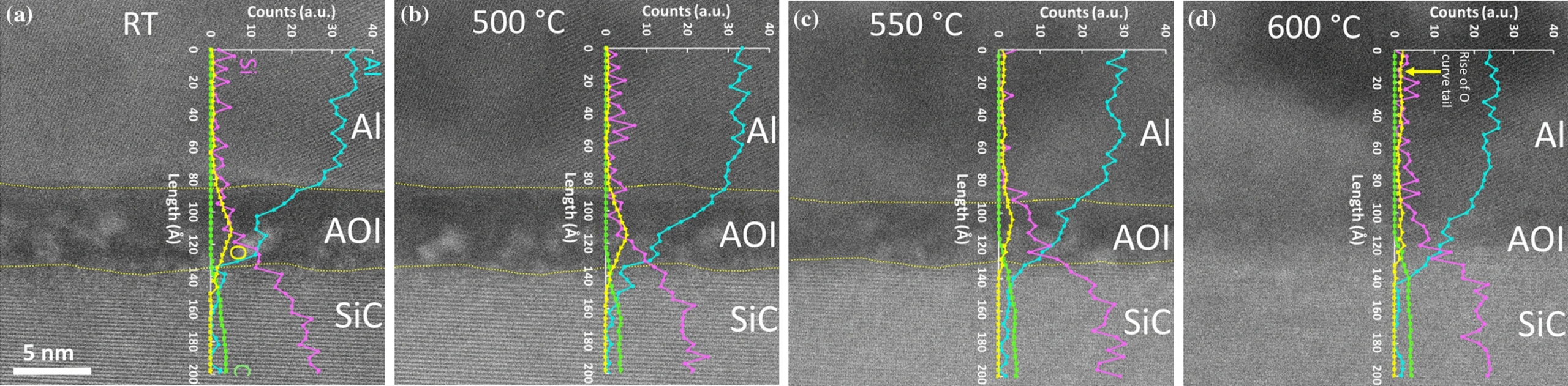

5) Perform in situ biasing experiments while cooling/heating: The Heating and Biasing Nano-Chips compatible with the Lightning Arctic holder contain biasing electrodes that can be used to apply and measure electrical signals either during cooling or during heating. Of course, the preparation of FIB lamellas on the Nano-Chips for electrical experiments is very crucial. There are already proven methods and tools developed for the Lightning system (like the DENSsolutions FIB stub) that can be used to prepare top-quality, short-circuit-free FIB lamellas on the Heating and Biasing chips for the Lightning Arctic system.

6) Wide compatibility of the sample carriers: Lightning Arctic has a similar Nano-Chip compatibility to the Lighting system, and works with Wildfire heating Nano-Chips and Lightning heating and biasing Nano-Chips. Moreover, the Lightning Arctic holder is also compatible with 3mm and lift-out TEM grids that can be used to study beam-sensitive materials at cryo-conditions without the need of using the Nano-Chips. This greatly expands the range of samples that the new in situ solution can work with.”

Read more about Lightning Arctic:

Download the Lightning Arctic brochure: