A comprehensive guide for data synchronization in operando gas and heating TEM

A team of experts develop a data synchronization method for operando gas and heating TEM via time delay calibration, enabled by the unique ability of the DENSsolutions Climate Nano-Reactor to perform nano-calorimetry.

Original article by Fan Zhang, Merijn Pen, Ronald G. Spruit, Hugo Perez Garza, Wei Liu, Dan Zhou

In recent years, operando gas and heating transmission electron microscopy (TEM) has become recognized as a powerful tool for creating time-resolved correlations between the environment, reaction products, energy transfer and material structures during reaction processes. Via operando gas and heating TEM, a detailed understanding of the relationship between the structural evolution of a catalyst and its performance can be achieved. Despite its many benefits, one inevitable issue with the technique is the intrinsic time delays that occur between different parameter measurement locations. These time delays must be calibrated in order for researchers to draw valid correlations and conclusions. Correlations without time delay calibration could lead to, for example, over/under-estimating critical temperatures and generating misleading relationships between catalytic structure and activity.

In recent research performed at the Dalian Institute of Chemical Physics (DICP), Chinese Academy of Sciences, where our advanced Climate G+ system is installed, Fan Zhang, Dr. Wei Liu and our own team of experts, including Merijn Pen, Ronald G. Spruit, Dr. Hugo Perez Garza and Dr. Dan Zhou, developed a data synchronization method to account for time delays in operando gas and heating TEM. Specifically, they systematically explored the relationship between delayed time and reaction conditions such as gas pressure, flow rate and gas composition. Based on the results, they developed open source scripts that can be used to achieve reliable and automated data synchronization via time delay characterization and calibration. The authors also developed a general protocol to perform automatic time delay calibration for all kinds of TEM setups.

The experimental setup

The experimental setup used in the study included the DENSsolutions Climate Gas Supply System (GSS), Climate in situ TEM holder, Climate Nano-Reactor, Gas Analyzer and Thermo Fisher Scientific Themis ETEM. In Figure 1a) below, a schematic view of the operando gas and heating TEM setup is presented. Generally, a gas will first travel from the GSS into the TEM, and then from the TEM into the Mass Spectrometer (MS), also known as the Gas Analyzer. This process is depicted in Movie 1 below. The different colors in the video visualize what happens when the gas composition is changed, where a new color represents a new gas mixture. In this visual depiction, it is shown that the gas composition measurement at the GSS is actually ahead in time of the measurements at the TEM. This is because the gas takes time to reach the sample. Moreover, the measurements from the MS are also delayed because the gas needs time to flow from the TEM to the MS. A more detailed account of the gas path and the components involved is provided below.

The GSS contains three gas bottles as well as three flow controllers that measure and regulate the gasses’ flow rates. The gasses are mixed using a unique on-the-fly mixing technique, where a user can change the gas composition dynamically as well as alter the gas environment within a matter of seconds. The mixed gas is then guided into the Nano-Reactor in the TEM through the holder, and then to the MS, which derives the outlet gas composition by measuring the partial pressures of reactants and products. Expectedly, as the gas travels through this path, considerable time delays occur. In fact, the researchers found that a user-set gas composition change in the GSS will only show changes in the MS after 79.1 seconds (see Figure 1b) below).

Movie 1: Movie depicting the gas path and time delays associated with operando gas and heating TEM.

Figure 1: (a) A schematic view of a gas cell based operando TEM gas path; (b) Illustration of time delay between GSS and MS. Here GSS data are measured by flow meter and MS by measuring the ionized gasses’ mass to charge ratio.

In Figure 2 below, a diagram of the operando gas and heating TEM setup used in this work is presented. The setup can be grouped in two ways: from a hardware perspective and from a gas path/TEM investigation perspective. In the case of the former grouping, the setup can be divided into GSS, TEM and MS. In the case of the latter grouping, the setup can be divided into pre-TEM, in-TEM and post-TEM. The researchers were able to synchronize the data from pre-, in- and post-TEM by first measuring and then calibrating the time delays involved.

Figure 2: A diagram of the operando gas and heating TEM setup.

Calorimetry-based time delay calibration

The DENSsolutions Climate system offers users the unique ability to perform nano-calorimetry, which comes in as a convenient feature in the calibration of time delays. Specifically, when a new gas type enters the Nano-Reactor, this is detected by the microheater because it is very sensitive to even the most minute changes in heat. Users can monitor the gas changing process due to the difference in the thermal properties of the different gasses flown through the Nano-Reactor, enabling the detection of what time the new gas has reached the sample. The unique on-chip calorimetry feature of our Nano-Reactor allows for calibration of the time delays, and therefore enables perfect synchronization between gas compositional changes, TEM imaging and spectroscopy data.

Relationship between time delay and various parameters

The next step for the researchers was to systematically explore the relationship between the delayed time and reaction conditions such as gas pressure, flow rate and gas composition. They found that the delayed time between different parts, in either of the two grouping mechanisms, is determined by the gas pressure and flow rate in the Nano-Reactor, as well as the total gas path length. They also found that the time delay has little dependence on the gas type. The investigation of the relationship between the time delay and the above-mentioned critical parameters allowed the researchers to develop a functional relationship. Using the established functional relationship, they were able to lay the foundation for manually and automatically calibrating the time delays.

Automation of data synchronization

Based on the investigations, the authors developed algorithms and scripts to enable the automatic data synchronization in operando gas and heating TEM. Specifically, two open source Python scripts have been written for characterizing and calibrating the time delays in experiments.

The first script characterizes the time delay curve, utilizing DENSsolutions Impulse API and ImpulsePy library to control and retrieve the measurements from the GSS, the heating control unit and the MS. It does this by alternating between different gas mixtures and measuring the time delays until these gas composition changes are detected in the calorimetry data of the microheater and in the partial pressure data from the Mass Spectrometer. It performs multiple gas composition switches at different flow-rates and pressures to collect enough data points to be able to fit the two characterization curves through them. These curves are the pre-TEM to in-TEM delay and the in-TEM to post-TEM delay characterization curves of that specific system. The characterization only needs to be performed once, after which the calibration file can be used repeatedly on any dataset measured by the same system.

The second script removes the time delays from a dataset by first splitting the system parameters into different sets: pre-TEM, in-TEM and post-TEM. Because the pressure and flow parameters can change over the duration of the experiment, the time delay correction amount is calculated and applied for every measurement in the dataset individually. The script then saves three corrected datasets (pre-TEM, in-TEM and post-TEM) individually with their own time resolution, and creates a synchronized log file in which the pre-TEM and post-TEM parameters are interpolated towards the in-TEM dataset timestamps. In Figure 3 below, an example of the synchronized data output from the time delay calibration script is presented. The data is then synchronized with the TEM imaging and spectroscopy data to achieve the complete operando gas and heating TEM data synchronization.

Figure 3: The synchronized data corrected by the time delay correction scripts.

General operation protocol

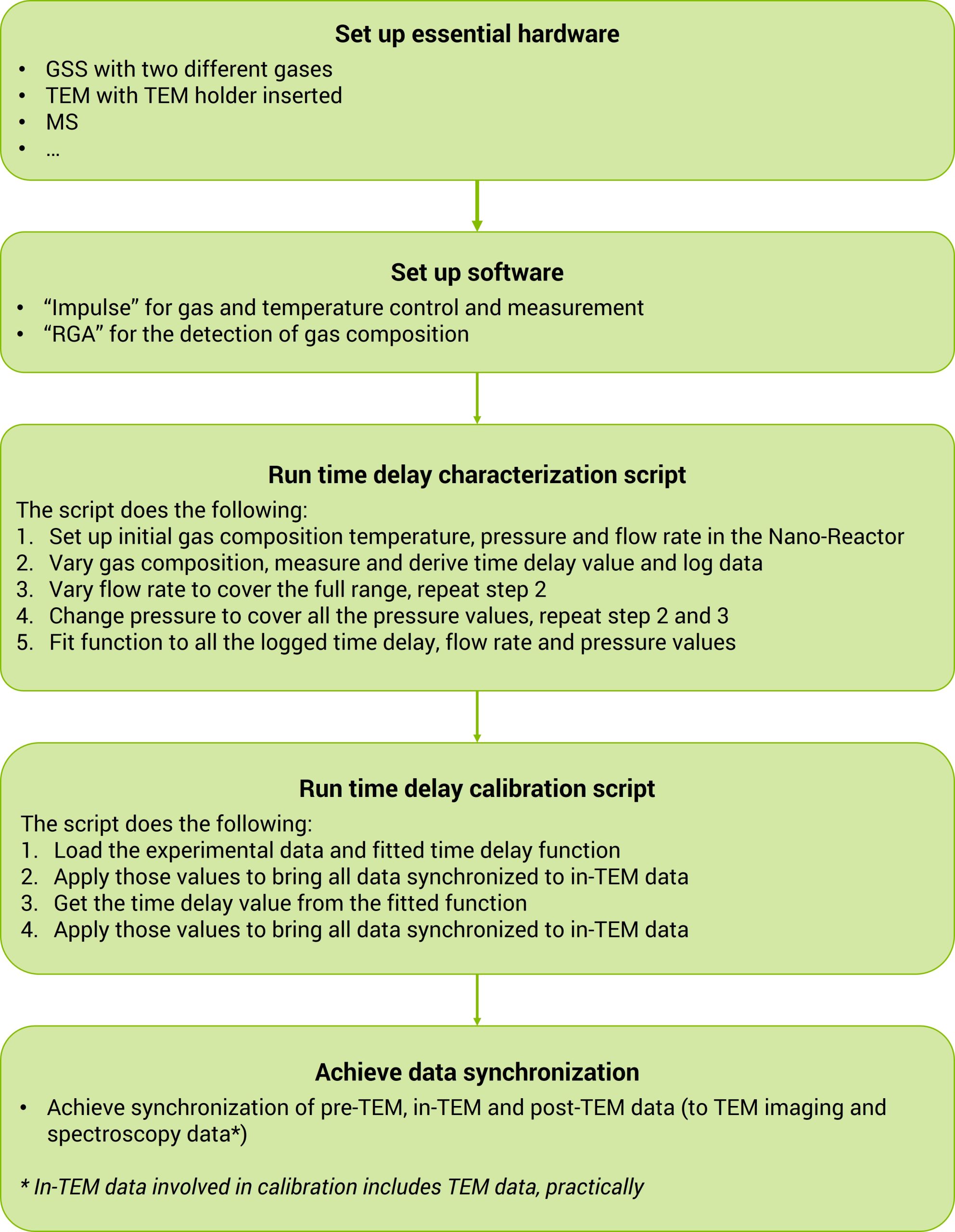

With the above conclusions and scripts, the authors have created a step-by-step guide for performing automatic time delay calibration for your own operando TEM setup. This protocol is summarized in Figure 4 below.

Figure 4: Schematic view of the operation protocol.

Conclusion

Time delay is an issue inherent to every gas supply system used in an operando gas and heating TEM setup. In a collaborative effort between DICP and DENSsolutions, the researchers have developed a data synchronization method to effectively address this problem. Specifically, by developing a functional relationship between delayed time and reaction conditions like gas pressure, flow rate and gas composition, the authors were able to develop open source scripts that characterize and calibrate the time delay automatically. On top of this, a conductive protocol is described such that any researcher can apply the data synchronization method to their own unique operando gas and heating experimental setup. Overall, this work is a major step forward in ensuring that researchers conducting operando gas and heating experiments are able to make valid correlations between critical parameters and provide the right conclusions and insights.

“The DENSsolutions Climate system is able to create an accurate working environment of what practical catalysts go through. Not only does the system facilitate the real-time observation of dynamic catalytic behavior, but it also enables the simultaneous monitoring of the performance of a catalyst by detecting the resulting products within the Nano-Reactor. By enabling this elaborate strategy of data synchronization in operando gas and heating TEM, Climate initiates the distinct functionality of correlating catalytic property with microstructural changes, which adds core value to what the technique of in situ TEM can reveal about a dynamic reaction.”

Prof. Dr. Wei Liu

Professor | Dalian Institute of Chemical Physics, CAS

Original article:

Discover our Climate solution:

Discover more publications made possible by Climate:

Scientists explore complex metal-support interactions under redox conditions using our Climate system

Via the DENSsolutions Climate system, a team of scientists uncover the dynamic interplay between platinum nanoparticles and titania support under reaction conditions.