Converting CO2 into a valuable energy carrier using a model In2O3 catalyst

New discoveries made possible by In Situ TEM gas and heating

Original article by Athanasia Tsoukalou, Paula M. Abdala, Dragos Stoian, Xing Huang, Marc-Georg Willinger, Alexey Fedorov and Christoph R. Müller. Published in the Journal of the American Chemical Society on 19 July 2019.

The direct hydrogenation of CO2 to methanol shows promise to be an important technique to reduce the amount of greenhouse gases in the atmosphere and thereby mitigate the negative effects of climate change while producing an important energy carrier. In his contribution to this article, Dr. Xing Huang has used In Situ TEM techniques to assess the limits of In2O3 catalytic performance in CO2 hydrogenation.

In Situ TEM Climate Nano-Reactor study

This catalyst research article by ETH Zürich provides a good demonstration on how in situ TEM experiments can add value to the study of reaction mechanisms. First, the structural changes in the catalyst material were studied with traditional TEM techniques before and after the CO2 reduction. By using the Climate in situ TEM system, the researchers were able to see the dynamics of the reaction, even at much lower pressures (0.8 vs. 20 Bar) than in the original operando experiment.

In Situ TEM video made using the DENSsolutions Climate system, at 300 °C, showing the co-existence of crystalline and amorphous phases as well as the transformation into film structures of the In2O3 catalyst.

Amorphization of the catalyst material inside the Nano-Reactor takes places in a few minutes, compared to hours in the capillary reactor. Re-activation of the catalyst is made easy by the Climate Gas Supply System since the hydrogen plus carbon-dioxide gas flow can be replaced by an oxygen flow at any moment.

“Direct observation using in situ TEM clearly reveals that the structure of In2O3 nanoparticles is highly dynamic under reaction conditions and irradiation of electron beam. The In2O3 is observed to transform into a dynamic structure in which both crystalline and amorphous phases coexist and continuously inter-convert.

This observation is in line with the operando XAS-XRD study revealing formation of the amorphous In0/In2O3 phase with time on stream. To sum up, combination of in situ TEM with other in situ/operando techniques enables to build a direct relationship between the structure and the catalytic performance of the In2O3 catalyst in CO2 hydrogenation to methanol.”

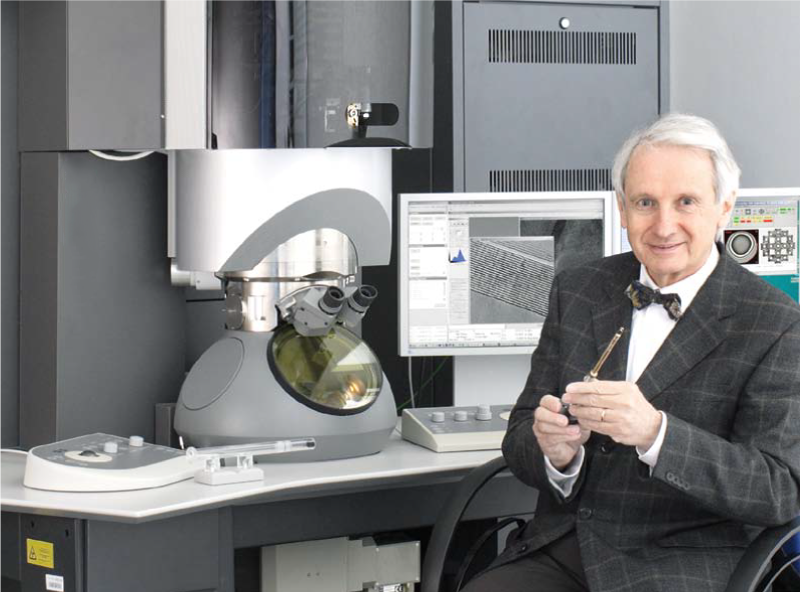

Co-author – Dr. Xing Huang, ETH Zürich

Learn more about our Climate system and Nano-Reactor:

Discover more publications made possible by our Climate system: