1st Climate holder delivers new research results at FHI Berlin

Original article by Milivoj Plodinec, Hannah C. Nerl, Frank Girgsdies, Robert Schlögl and Thomas Lunkenbein. Published in ACS Catalysis.

In January 2016 DENSsolutions installed the 1st Climate holder with serial number #001 at FHI Berlin. The users at that time, Dr. Marc Willinger and Dr. Ramzi Farra, have since moved on to other institutes where they continue to use the Climate system for their research. In the mean time at FHI Berlin, new users took over the In Situ research activities and are producing excellent results with holder #001 which has since been upgraded with an EDS compatible tip.

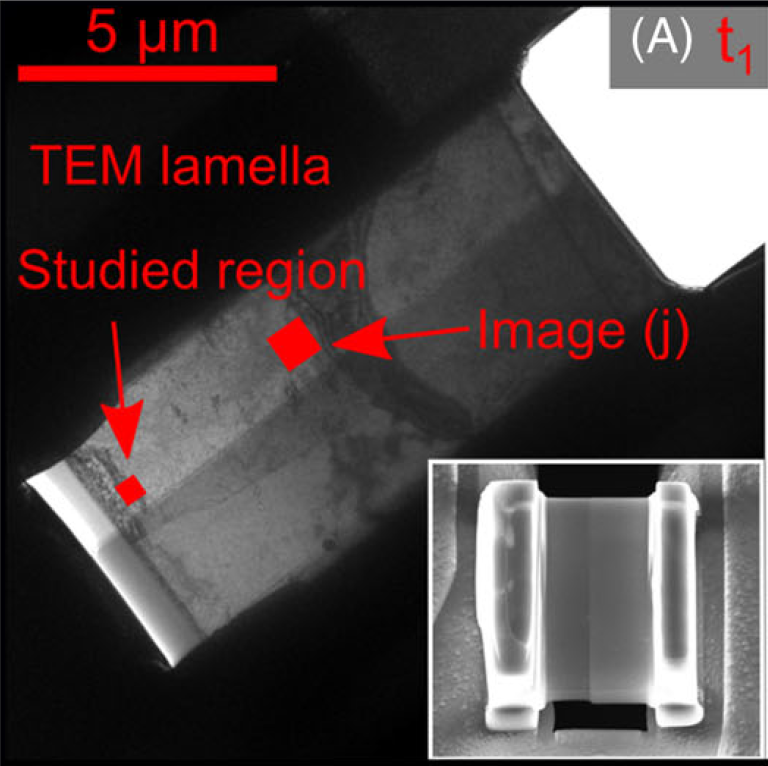

Click here to read their recent publication in ACS Catalysis. The article demonstrates the stability of the Climate holder and Nano-Reactor. It also demonstrates the compatibility with other techniques like SAED and Mass Spectroscopy. By correlating all the data from these in situ experiments the mysteries of catalytic processes at the nanoscale will be unraveled!

“It was the combination of the DENSsolution Climate gas cell TEM holder with our homebuilt gas feed and analyzing system that enabled us to assign different parts of chemical dynamics of Pt catalyst to different activity regimes during CO Oxidation. The high sensitivity of our gas feed and analysing system ensured the detection of conversion, while the software and MEMS chip provided by DENSsolution ensured the stability over two weeks to perform experiment, even at extreme temperatures (up to 1000°C) for several hours.”

Dr. Milivoj Plodinec

Postdoc

Dr. Frank Girgsdies

Staff scientist

Dr. Thomas Lunkenbein

Group leader

Learn more about our Climate system and Nano-Reactor:

Discover more publications made possible by our Climate system:

Read the original article: