Gas Analyzer supporting ex situ Catalyst experiments

The experiment

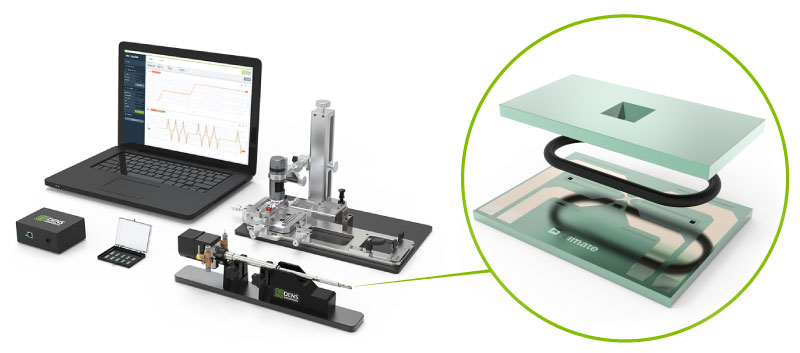

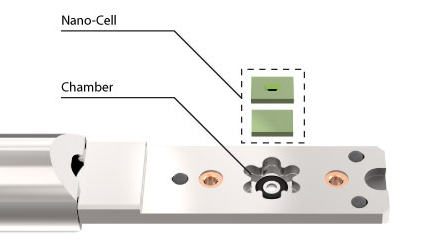

We used palladium nanoparticles for our catalyst These particles were dropcasted inside a Climate MEMS based Nano-Reactor. For the gas supply we used the Climate G+ system which allows for up to 3 gases to be mixed. We loaded the system with oxygen and methane as reactive gases and measured carbon monoxide and carbon dioxide as reaction products.

Catalyst performance

First we used the gas analyzer combined with our accurate temperature control to measure the catalyst performance. The supply of reactants was kept at a constant level (figure 1 – middle graph) while we used our Impulse software to automatically ramp up the temperature of the Nano-Reactor from 300 to 700 °C in 60 seconds (figure 1 – top graph). As a result we measured the level of reactant gases dropping and the level of reaction products rising (figure 1 – bottom graph). We see the levels stabilizing when the temperature is constant.

High activity phase shifting

At t = 500 seconds we use our Impulse software to drop the level of methane in steps of 0,5%. Measuring the CO2 level with our gas analyzer we can clearly see the influence of the first drop in concentration. The CO2 production rate starts to more unstable. By dropping the concentration with another 0,5%, the frequency of the fluctuations increases and, after the third drop of concentration, the catalyst starts to shift back to its normal activity phase, stabilizing the CO2 production after the fourth drop.

High time resolution

We zoomed in at areas A and B and plotted the results from the gas analyzer as well as those from the power dissipated by our 4-point probe temperature control system (see figure 3). This allows us to correlate the two measurements. We see that the reaction gases are in counter phase of each other and that their extremes are in line with the tops of the measured power. This shows not only a very high stability in temperature control but also a very high time resolution.

Conclusions

Thanks to our high accuracy gas analyzer and heating control and measurement, you are able to do ex situ experiments that can give you valuable data. This data can lead to new discoveries or can be used to prepare your in situ experiment better.

“Using the Climate G+ in combination with the Gas Analyzer allows you to characterize your catalyst sample ex situ, finding the best gas and temperature conditions for your reaction, and with this data to go to the TEM to finalize your research with real in situ images and spectroscopy.”

Download the

Gas Analyzer Application Note

The experiment

We used palladium nanoparticles for our catalyst These particles were dropcasted inside a Climate MEMS based Nano-Reactor. For the gas supply we used the Climate G+ system which allows for up to 3 gases to be mixed. We loaded the system with oxygen and methane as reactive gases and measured carbon monoxide and carbon dioxide as reaction products.

Catalyst performance

First we used the gas analyzer combined with our accurate temperature control to measure the catalyst performance. The supply of reactants was kept at a constant level (figure 1 – middle graph) while we used our Impulse software to automatically ramp up the temperature of the Nano-Reactor from 300 to 700 °C in 60 seconds (figure 1 – top graph). As a result we measured the level of reactant gases dropping and the level of reaction products rising (figure 1 – bottom graph). We see the levels stabilizing when the temperature is constant.

High activity phase shifting

At t = 500 seconds we use our Impulse software to drop the level of methane in steps of 0,5%. Measuring the CO2 level with our gas analyzer we can clearly see the influence of the first drop in concentration. The CO2 production rate starts to more unstable. By dropping the concentration with another 0,5%, the frequency of the fluctuations increases and, after the third drop of concentration, the catalyst starts to shift back to its normal activity phase, stabilizing the CO2 production after the fourth drop.

High time resolution

We zoomed in at areas A and B and plotted the results from the gas analyzer as well as those from the power dissipated by our 4-point probe temperature control system (see figure 3). This allows us to correlate the two measurements. We see that the reaction gases are in counter phase of each other and that their extremes are in line with the tops of the measured power. This shows not only a very high stability in temperature control but also a very high time resolution.

Conclusions

Thanks to our high accuracy gas analyzer and heating control and measurement, you are able to do ex situ experiments that can give you valuable data. This data can lead to new discoveries or can be used to prepare your in situ experiment better.

“Using the Climate G+ in combination with the Gas Analyzer allows you to characterize your catalyst sample ex situ, finding the best gas and temperature conditions for your reaction, and with this data to go to the TEM to finalize your research with real in situ images and spectroscopy.”