Introducing our new DENSsolutions brand identity

We care

At the very core of all of our innovations, our technology and our solutions is that we care about your research. We want you to have the best possible equipment, be able to discover new phenomena and get unique yet reliable results that allow you to answer your scientific questions and publish in high impact journals.

This care goes beyond design and manufacture, we provide support whenever and wherever it is needed. We also aim to be the global hub for the In Situ research community, connecting you with peers all across the world.

CTO Hugo Pérez with University of Oxford Professor Angus Kirkland

We innovate

With researchers constantly pushing the boundaries of knowledge, we make sure that our systems push the boundaries of innovation. This is at the heart of our second core value: we innovate. This way, you can rest assured that you are operating the best stimuli supply and measurement systems on the market, giving you the necessary tools to make groundbreaking discoveries. Whatever the application, from materials science to catalysis, you can ultimately create a sample environment almost identical to the real world.

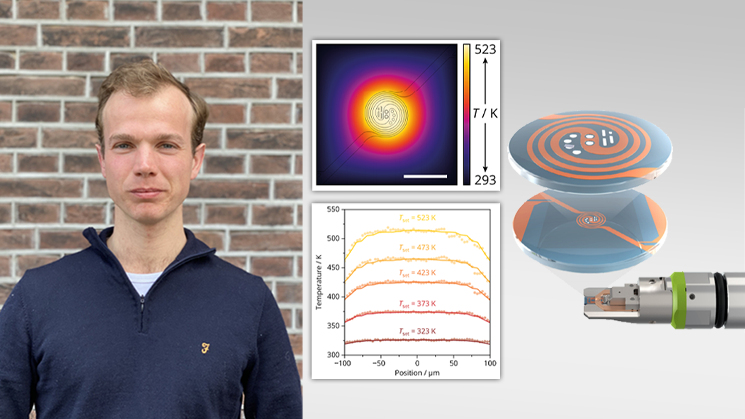

Previous Mechatronics Engineer Diederik Morsink observing a holder in our offices

We deliver

We acknowledge how precious your time is and how crucial our cutting-edge technology is for your research. Through our worldwide distributor network, we strive to make sure that you receive your equipment in time. In efforts to adapt to the travel limitations of today, we have comprehensive remote installations and trainings for all of our solutions so that you can operate our systems with confidence, no matter where you are.

Warehouse Supervisor Magda Wierzba handling Climate system delivery

New measuring technique proves exceptional temperature accuracy of our Wildfire Nanochip