Scientists develop a powerful distributed electron microscopy technique to study complex reactions in solution

Using our Ocean system, scientists demonstrate the power of combining multiple electron microscopy methods, showing for the first time how the desilication mechanism of zeolite crystals proceeds in 3D on the single particle level.

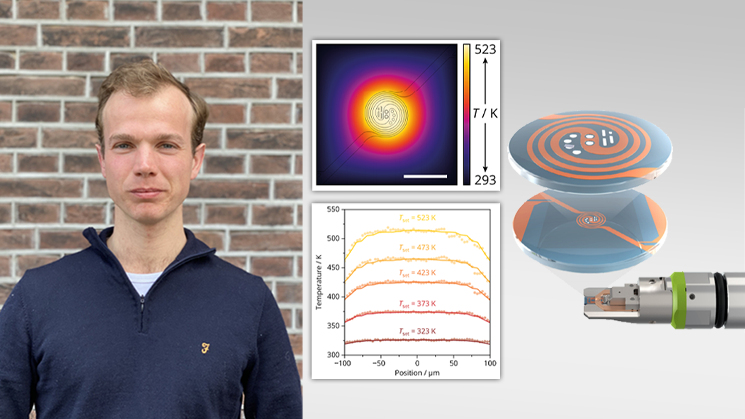

Dr. Hanglong Wu and his colleagues from the Eindhoven University of Technology, ETH Zurich and University of California, Irvine provide a robust answer to this pressing question by developing a novel approach for studying complex reactions in solution. This concept, which they term a “distributed electron microscopy (EM) method” combines information from multiple EM methods, including LPEM, cryogenic EM and cryo-electron tomography. To demonstrate this powerful method, Dr. Wu and his colleagues use our dedicated LPEM solution to study the desilication mechanism of zeolite crystals. They show for the first time with an exceptional level of confidence how the reaction proceeds in 3D on the single particle level. Moreover, they show how LPEM can be combined with cryo-EM to study a complete reaction which is essential to rule out beam-induced effects in LPEM experiments.

The desilication study

Dr. Wu and his colleagues employ a distributed electron microscopy method to study the desilication process in zeolite crystals, showing how the reaction proceeds in 3D and what controls the desilication kinetics. This distributed approach enables them to explore and understand the native mechanism at hand, exploiting the power of each imaging modality – LPEM, cryogenic EM (cryo-EM) and cryo-electron tomography (cryo-ET). The researchers use Al-zoned ZSM-5 zeolites, which have an aluminum-rich rim and an aluminum-poor core, as a model system, to study the desilication process. The reason this is an ideal model system is that ZSM-5 crystals have a complex 3D morphology and are also considerably beam-sensitive.

The two videos below respectively show the automated sample loading process assisted by a liquid handling machine called SciTEM, and how the desilication process was initiated via the manual flowing of an NaOH solution into the cell.

Movie 1: Movie showing the SciTEM-assisted sample loading process, where a tiny droplet (~ 300 pL) containing zeolite crystals was deposited on the centre of the viewing window area.

Movie 2: Movie showing that the liquid cell is gradually filled with 0.6 M NaOH

Using LPTEM to observe the desilication process

Using LPTEM, Dr. Wu and his colleagues monitored the desilication process of individual parent zeolite crystals in multiple areas of a single cell. In the movie below, the desilication process of three pre-etched zeolite crystals can be observed over a 3-hour period. In contrast, for the crystals without the pre-etching treatment, the researchers find that the zeolites were only partially desilicated after 30 h in the liquid cell.

Movie 3: Movie showing the desilication process of three pre-etched zeolite crystals. On the left is the raw data movie and on the right a 30-frame-averaged data movie

LPTEM vs. LPSTEM

The LPSTEM results (Figure 1) observed by the researchers were significantly different from the LPEM observations. Dr. Wu and his colleagues believe that the differences mainly originate from contrast formation mechanisms and the localized electron distribution of each imaging mode. On one hand, LPTEM enables the quick control of the localized low electron flux homogeneously across the field of view. However, the appearance of diffraction contrast from the defects can be problematic for quantitative contrast interpretations. On the other hand, LPSTEM enables the better understanding of sample contrast evolution due to being less affected by diffraction effects. Simultaneously, however, the focused high flux electron probe might bring localized structural changes caused by radiolysis of the sample itself and water.

Figure 1: Desilication process of Al-zoned ZSM-5 crystals imaged by pulsed LP-STEM. Scale bars: 200 nm.

Using cryo-EM and cryo-ET to observe the desilication process

Monitoring the desilication process using cryo-EM was the next step for Dr. Wu and his colleagues. Unlike LPEM, cryo-EM enabled the researchers to monitor the process in the absence of confinement and electron beam effects. In practice, cryo-TEM is generally performed prior to an in situ study, as it provides key information on what intermediate structures are present and, most importantly, how they evolve statistically over time. The figure below shows the cryo-EM results presented for crystals at different time points, where the stages of desilication are in agreement with the collective LPEM data and the general sample evolution observed by cryo-EM.

Figure 2: Desilication process of ZSM-5 zeolites monitored by cryo-TEM (a) and cryo-STEM (b). Scale bars: 200 nm.

Figure 3: Segmented surface rendering of the 12 h desilicated zeolite crystal.

Movie 4: Movie showing the cryo-electron tomography 3D reconstruction of a 12 h desilicated zeolite crystal

Novelty in findings

This study is a major step forward in understanding the role that the electron beam plays in LPEM experiments. Ultimately the collective results reveal that the desilication mechanism of zeolite crystals occurs via a two-step anisotropic etching process. This complex mechanism was only discovered due to the novel distributed approach that Dr. Wu and his colleagues employed. Particularly, the combination of LPEM and cryo-EM was essential to rule out the effects of the electron beam in the LPEM experiments.

Considering the strength of this distributed method, Dr. Wu and his colleagues anticipate that the combination of LPEM and cryo-EM will become a standard approach for understanding reaction mechanisms in aqueous solutions and could even be extended to non-aqueous solutions. Moreover this method will enable scientists to draw robust conclusions on the 3D reaction mechanisms of other important beam-sensitive material systems, such as biomaterials and proteins, whereby some grand challenges in materials science and life sciences could be potentially solved.

Postdoctoral Researcher | Eindhoven University of Technology

Original article:

Discover our LPEM solutions:

Discover more publications made possible by our LPEM solutions:

Scientists present novel approaches to map and control liquid thickness in LPEM experiments