Counting atoms in operando conditions

The efficiency of a catalyst relies on the capability of promoting reactions directly on its surface. Thus, there have been many attempts to accurately determine the atomic structure at the surface when gasses are flown on the catalytic sample.

Obviously, in situ electron microscopy is the best candidate to provide that answer, due to the possibility of recording ultra high resolution information while flowing gasses on the sample at high temperature. However, due to the nature of the imaging process, only 2D projections can be captured, severely limiting our understanding of the catalytic process.

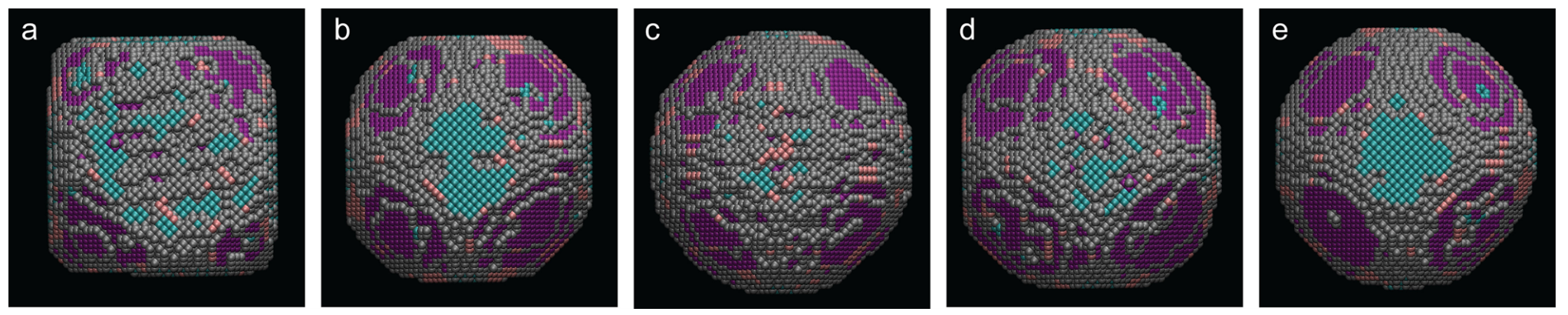

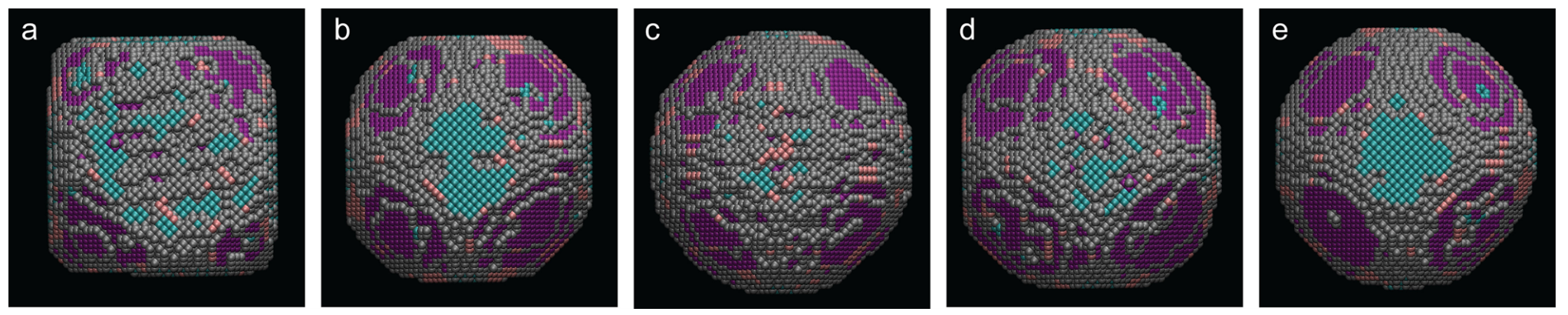

Researchers at EMAT, Antwerp, have combined the high stability of the Climate in situ gas&heating solution with their multi-year experience on developing algorithms to accurately retrieve 3D structures down to atomic resolution. Platinum nanoparticles were cyclically exposed to reducing and oxidizing gas mixtures to promote and study surface re-faceting; after each step, high resolution STEM images were acquired and they were analyzed by means of a novel methodology based on deep convolutional neural networks (CNN) and molecular dynamics simulations.

Researchers at EMAT, Antwerp, have combined the high stability of the Climate in situ gas&heating solution with their multi-year experience on developing algorithms to accurately retrieve 3D structures down to atomic resolution. Platinum nanoparticles were cyclically exposed to reducing and oxidizing gas mixtures to promote and study surface re-faceting; after each step, high resolution STEM images were acquired and they were analyzed by means of a novel methodology based on deep convolutional neural networks (CNN) and molecular dynamics simulations.

The results show that it is now possible to obtain very accurate 3D atomic models that enable researchers to “see and count” atoms which are sitting on the surface. These new findings will allow a much deeper characterization and understanding of the processes behind catalytic reactions.

Obviously, in situ electron microscopy is the best candidate to provide that answer, due to the possibility of recording ultra high resolution information while flowing gasses on the sample at high temperature. However, due to the nature of the imaging process, only 2D projections can be captured, severely limiting our understanding of the catalytic process.

Researchers at EMAT, Antwerp, have combined the high stability of the Climate in situ gas&heating solution with their multi-year experience on developing algorithms to accurately retrieve 3D structures down to atomic resolution. Platinum nanoparticles were cyclically exposed to reducing and oxidizing gas mixtures to promote and study surface re-faceting; after each step, high resolution STEM images were acquired and they were analyzed by means of a novel methodology based on deep convolutional neural networks (CNN) and molecular dynamics simulations.

Researchers at EMAT, Antwerp, have combined the high stability of the Climate in situ gas&heating solution with their multi-year experience on developing algorithms to accurately retrieve 3D structures down to atomic resolution. Platinum nanoparticles were cyclically exposed to reducing and oxidizing gas mixtures to promote and study surface re-faceting; after each step, high resolution STEM images were acquired and they were analyzed by means of a novel methodology based on deep convolutional neural networks (CNN) and molecular dynamics simulations.The results show that it is now possible to obtain very accurate 3D atomic models that enable researchers to “see and count” atoms which are sitting on the surface. These new findings will allow a much deeper characterization and understanding of the processes behind catalytic reactions.

Does fluidic control matter?

In situ liquid experiment featuring Copper deposition

It can be seen that high flow rates (1200 nl/min) promote plating of the electrode. However, when switching to lower flow rate values (50 nl/min) the growth mechanism changes and dendrites appear.

The pressure-based liquid pump, the absence of dead volumes and the defined liquid channel all contribute to a very responsive system that allows to accurately vary experimental conditions within seconds.

Meet the cover images

All of our new brochures feature a cover image which has been made available by our customers. Why did we select them?

The image was acquired just before the launch of the improved heating chip. The sample is a gold-palladium nanoparticle imaged at 1000 °C on a Thermo Scientific Titan equipped with an image corrector and our Wildfire in situ heating system. We selected this image because it shows that the native resolution and drift rate of your microscope are not affected at all by the extreme temperatures that are possible with the DENSsolutions Wildfire system.

Courtesy of EMAT, Antwerp (BE)

Flexoelectrics: the sample imaged is Bi1/2Na1/2TiO3 – SrTiO3 (aka BNT-ST). It went through a thermal treatment directly on the chip in order to obtain the desired properties, then it was imaged at 800 °C with electric fields ranging from -220 kV/cm to +220 kV/cm. Images were acquired using the Lightning HB+ on a JEOL ARM. The image was chosen because it explains why we need to have the flexibility to reach extreme conditions, both in terms of temperature and electric fields. The sample showed, unexpectedly, nano-domains at temperatures much higher than previously reportedl.

Courtesy of Leopoldo Molina-Luna, TU Darmstadt (DE)

The image shows a Pd particle imaged system at 500 C in 1 bar of He/CO. The image was recorded with our Climate G+ on a Thermo Scientific Titan. Although having 1 bar inside the Nano-Reactor may lead to think that the native resolution of your microscope will be affected, the image demonstrates an information transfer of 55 pm. Thus, the Climate enables users to observe the finest dynamical structural changes in catalytic processes..

Courtesy of Prof. Wang, Zheijang University (CN)

The image captured from a video shows a protein, ferritin, imaged with our in situ liquid solution on a JEOL 2110F equipped with a direct electron detector camera. The protein has an outer diameter of 12 nm and we can image it with a resolution not too far from 1 nm. We can observe brownian motion, rotation, agglomeration and fusion, thanks to the stability and reliability of our in situ liquid solution.

Courtesy of Prof. Battaglia, UCL (UK)

The image was acquired just before the launch of the improved heating chip. The sample is a gold-palladium nanoparticle imaged at 1000 °C on a Thermo Scientific Titan equipped with an image corrector and our Wildfire in situ heating system. We selected this image because it shows that the native resolution and drift rate of your microscope are not affected at all by the extreme temperatures that are possible with the DENSsolutions Wildfire system.

Courtesy of EMAT, Antwerp (BE)

Flexoelectrics: the sample imaged is Bi1/2Na1/2TiO3 – SrTiO3 (aka BNT-ST). It went through a thermal treatment directly on the chip in order to obtain the desired properties, then it was imaged at 800 °C with electric fields ranging from -220 kV/cm to +220 kV/cm. Images were acquired using the Lightning HB+ on a JEOL ARM. The image was chosen because it explains why we need to have the flexibility to reach extreme conditions, both in terms of temperature and electric fields. The sample showed, unexpectedly, nano-domains at temperatures much higher than previously reportedl.

Courtesy of Leopoldo Molina-Luna, TU Darmstadt (DE)

The image shows a Pd particle imaged system at 500 C in 1 bar of He/CO. The image was recorded with our Climate G+ on a Thermo Scientific Titan. Although having 1 bar inside the Nano-Reactor may lead to think that the native resolution of your microscope will be affected, the image demonstrates an information transfer of 55 pm. Thus, the Climate enables users to observe the finest dynamical structural changes in catalytic processes..

Courtesy of Prof. Wang, Zheijang University (CN)

The image captured from a video shows a protein, ferritin, imaged with our in situ liquid solution on a JEOL 2110F equipped with a direct electron detector camera. The protein has an outer diameter of 12 nm and we can image it with a resolution not too far from 1 nm. We can observe brownian motion, rotation, agglomeration and fusion, thanks to the stability and reliability of our in situ liquid solution.

Courtesy of Prof. Battaglia, UCL (UK)

Lightning featured on Nature Communications

Materials with switchable polarization are indispensable in memory devices, sensors, actuators, and transducers. In this publication Leopoldo Molina-Luna et al reported an unexpected phenomenon, the appearance of domain-like nanoregions (DLNRs) at extreme temperatures. The origin of the phenomenon can be ascribed to flexoelectricity, an intrinsic property of dielectric materials that can generate polarization under a strain induced by compositional gradients. To examine the origin of the DLNRs experimentally, the authors applied electric fields up to ±22 kV/mm at 800 °C and observed the dynamics by means of high resolution imaging. This discovery opens up a new exciting science and will certainly motivate the study and development of other high-temperature flexoelectric nanomaterials.

One of the many benefits of the Lightning in situ heating&biasing solution is the unique possibility of applying extreme electric fields at the highest temperature. This has certainly played an important role in the discovery the phenomenon that led to the Nature publication.

Book your Live Demonstration and see how the Lightning can boost your research.

One of the many benefits of the Lightning in situ heating&biasing solution is the unique possibility of applying extreme electric fields at the highest temperature. This has certainly played an important role in the discovery the phenomenon that led to the Nature publication.

Book your Live Demonstration and see how the Lightning can boost your research.

X-Rays Safety

Working with high energy electrons (up to 300 kV in current commercial systems) means a large amount of X-Rays are generated inside the microscope: manufacturers are well aware of the potential risks and they take the utmost care to make sure you can operate the electron microscope without being harmed by lethal radiation.

What about DENSsolutions’ holders then? We would like to share our tests results to show we take exactly the same precautions as the original manufacturers.

In this case we performed the tests with one of the TEM providers, with OEM operators and approved measuring devices. The standard protocol was used (beam current equal to >75 nA)

What about DENSsolutions’ holders then? We would like to share our tests results to show we take exactly the same precautions as the original manufacturers.

In this case we performed the tests with one of the TEM providers, with OEM operators and approved measuring devices. The standard protocol was used (beam current equal to >75 nA)

Maximum allowed radiation level: 1000 nS/h

Wildfire DT/Lightning: 235 nS/h Climate/Stream: 223 nS/h

For any further questions please do not hesitate to contact your DENSsolutions Sales Representative