Operando TEM using Climate G+ to study Metal catalyst behavior during reaction

Original article by See Wee Chee, Juan Manuel Arce-Ramos, Wenqing Li, Alexander Genest & Utkur Mirsaidov. Published in Nature Communications volume 11, Article number: 2133 (2020) .

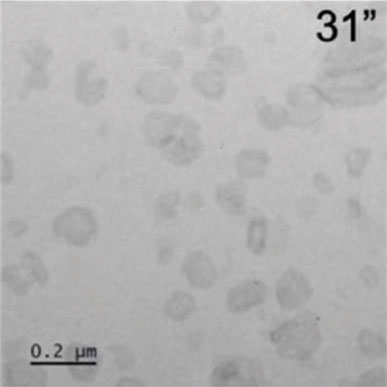

The catalytic performance of noble metal nanoparticles (NPs) is decided by their surface structure. Hence, understanding the structural dynamics of nanoparticles during catalysis is necessary for the design of improved catalysts that can lead to significant reductions in energy consumption for industrial catalytic processes. Using the DENSsolutions Climate system, scientists from National University of Singapore (NUS) showed that they were able to capture structural changes in Palladium (Pd) NPs during CO oxidation under realistic operating environments and correlate those changes with the NPs’ catalytic activity.

The Pd NPs showed an inactive faceted structure at low temperatures which changed to an active more rounded structure at higher temperatures. This change in NP structure and activity reverses when the temperature is reduced. The reversibility of NP structural transformations has important implications for our understanding of active catalyst structures and reinforces the need for direct operando observations.

Climate system

For this research, the Climate G+ system was used in combination with the DENSsolutions Gas Analyzer. The system enabled the researchers to attribute the changes in catalytic activity to the observed structural changes, which was further confirmed by thermodynamic calculations. Matching the high-resolution image sequences with outlet gas composition changes helped the authors to understand how the NP structure can influence the availability of active sites on a NP’s surface.

This research exemplifies how the different data streams from the Climate G+ (calorimetry), the Gas Analyzer (partial pressure) and the TEM detector (HR-TEM image) can be correlated into meaningful results:

TEM detector

Calorimetry

Gas analyzer

The inline mass spectrometry (Gas Analyzer) was critical for establishing the correlation between nanoparticle and catalyst activity. The low thermal drifts allow us to follow the nanoparticles during heating and cooling ramps.”

Department of Physics and Department of Biological Sciences.

National University of Singapore

Learn more about our Climate system:

Discover more publications made possible by our Climate system:

Read the original article: