Nano-Reactor

A revolutionary technology for understanding chemical reactions

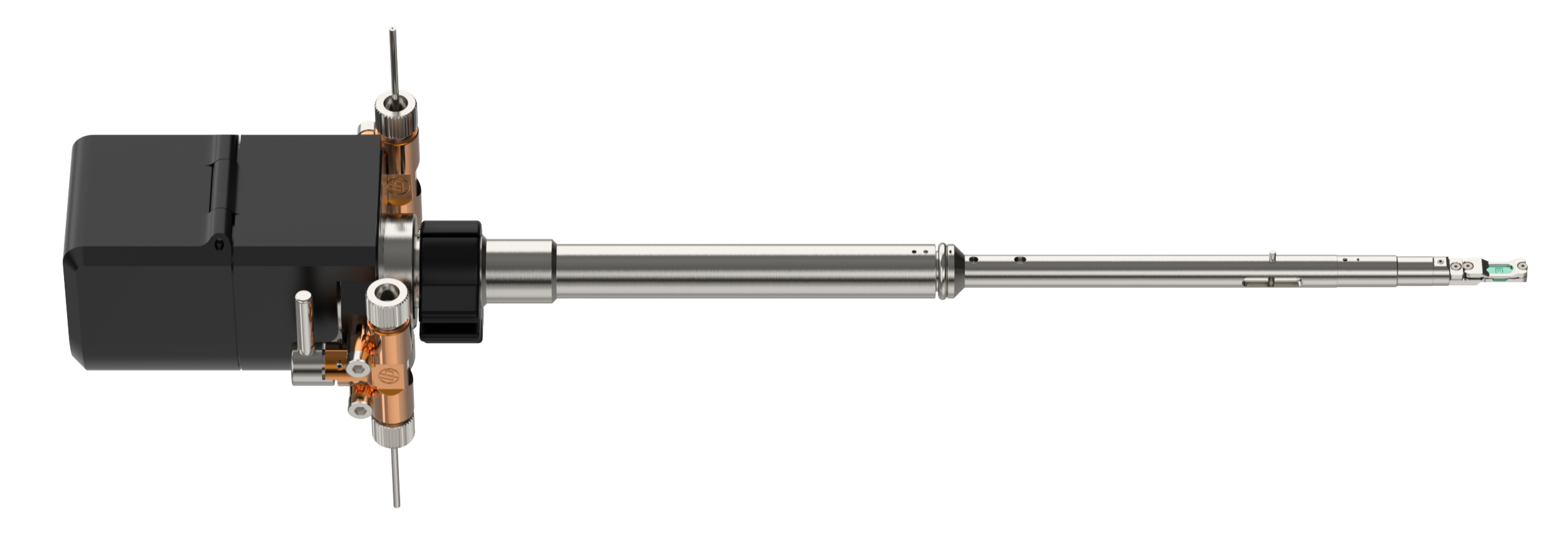

The Climate Infinity Nano-Reactor is a MEMS-based device that acts as a sample carrier enabling a unique gas, heating and biasing environment within an electron microscope. Replicating a real-world industrial chemical reactor, the Nano-Reactor enables sub-Angstrom resolution imaging and analysis of gas reactions.

MEMS-based Sample Carriers

The heart of our technology

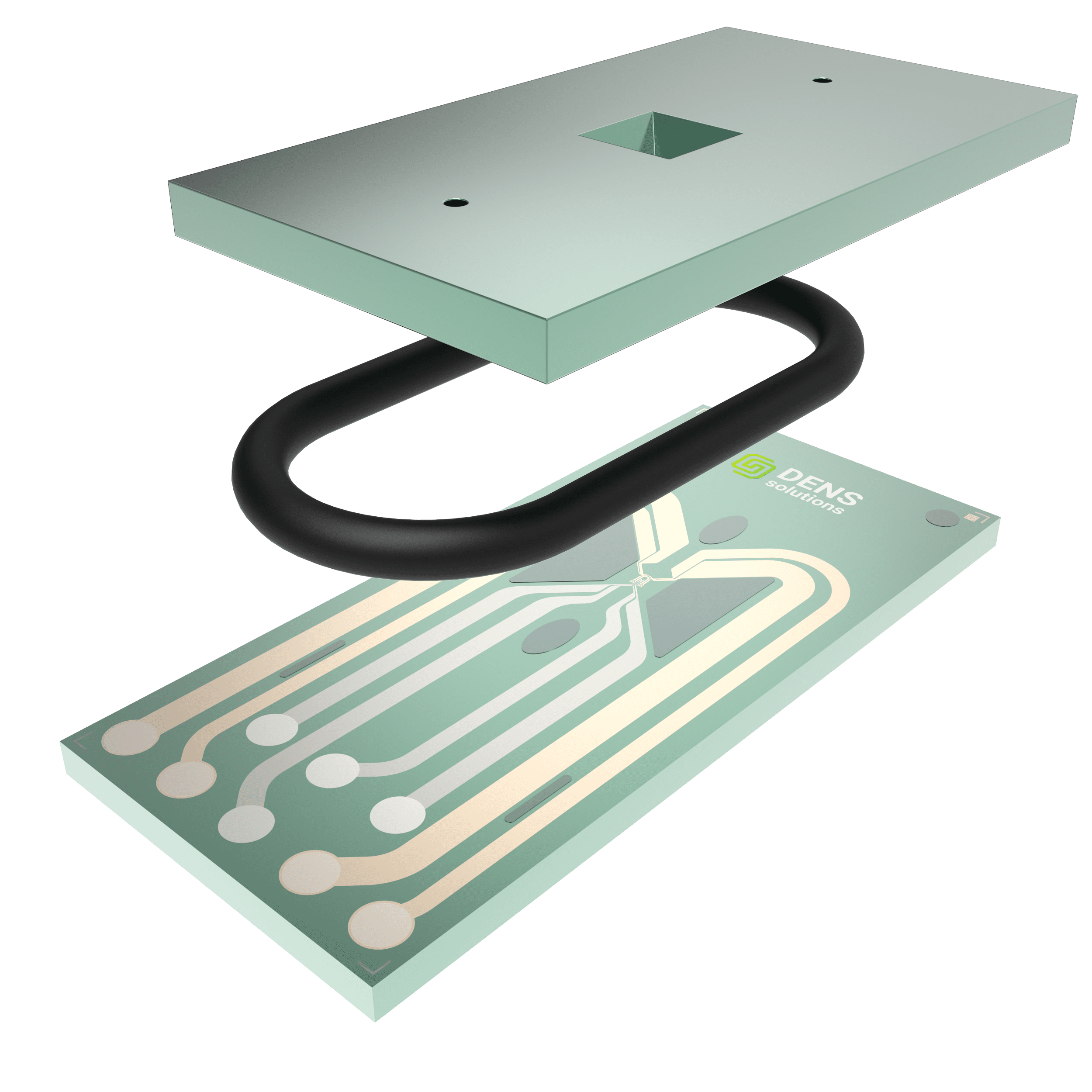

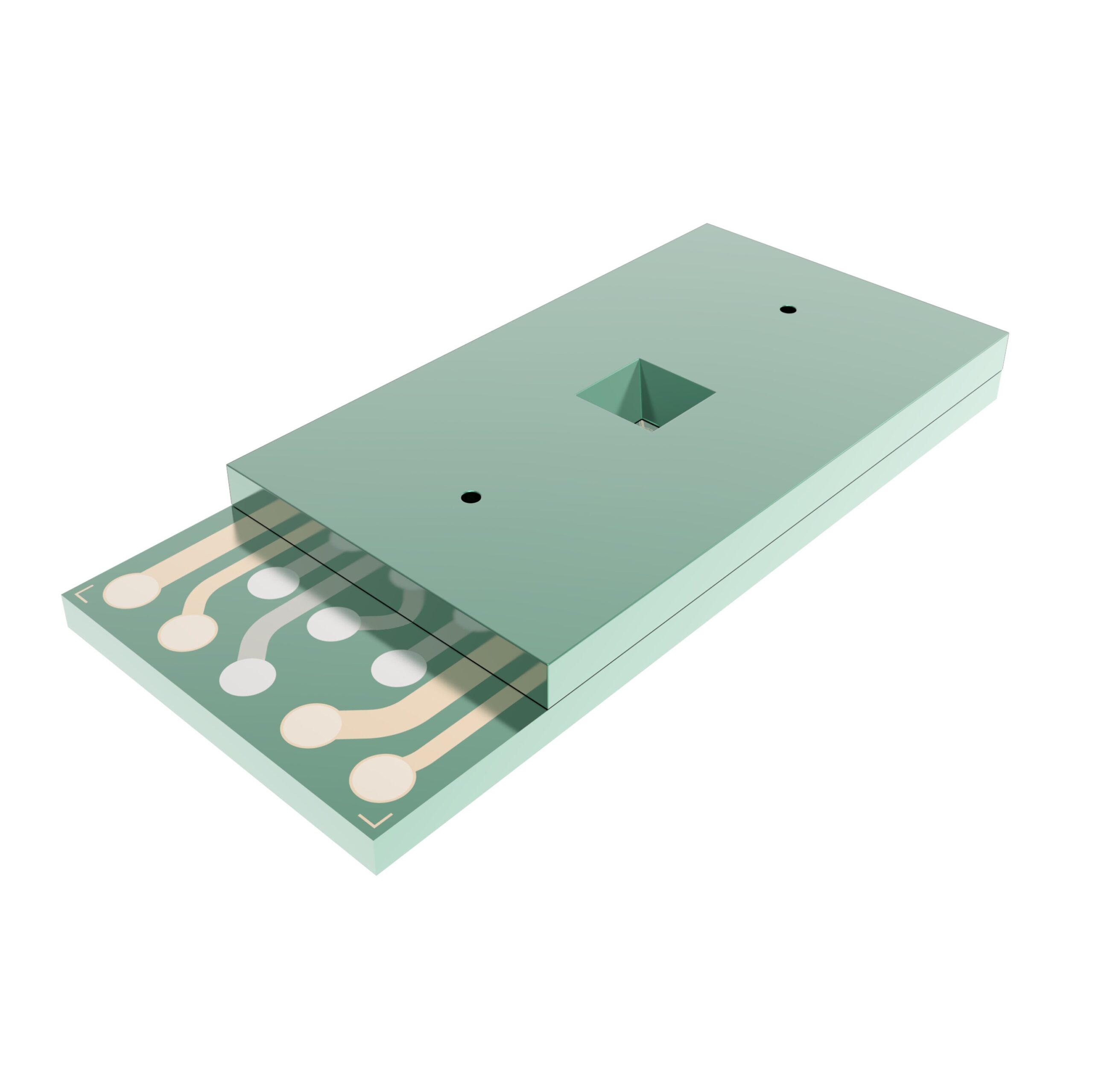

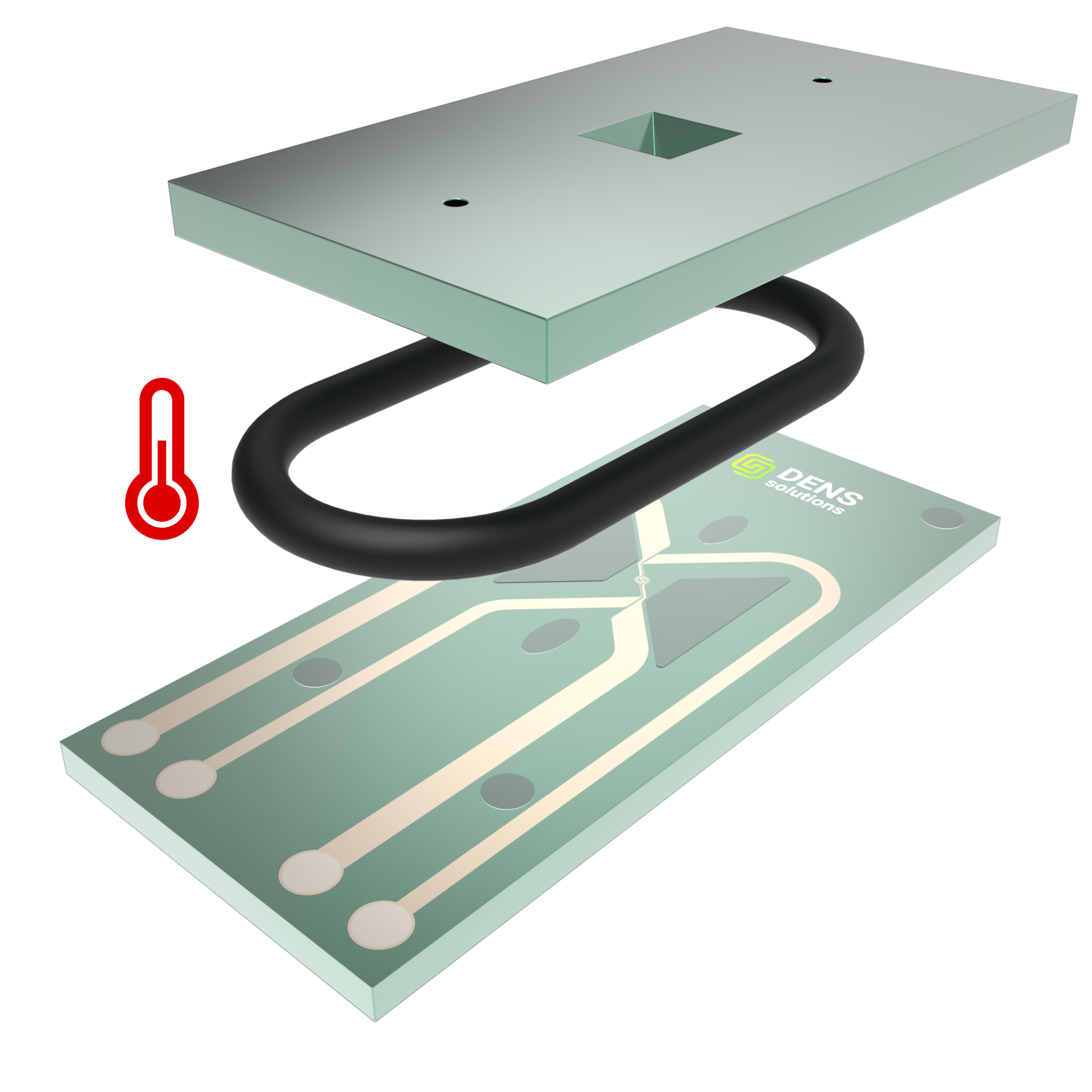

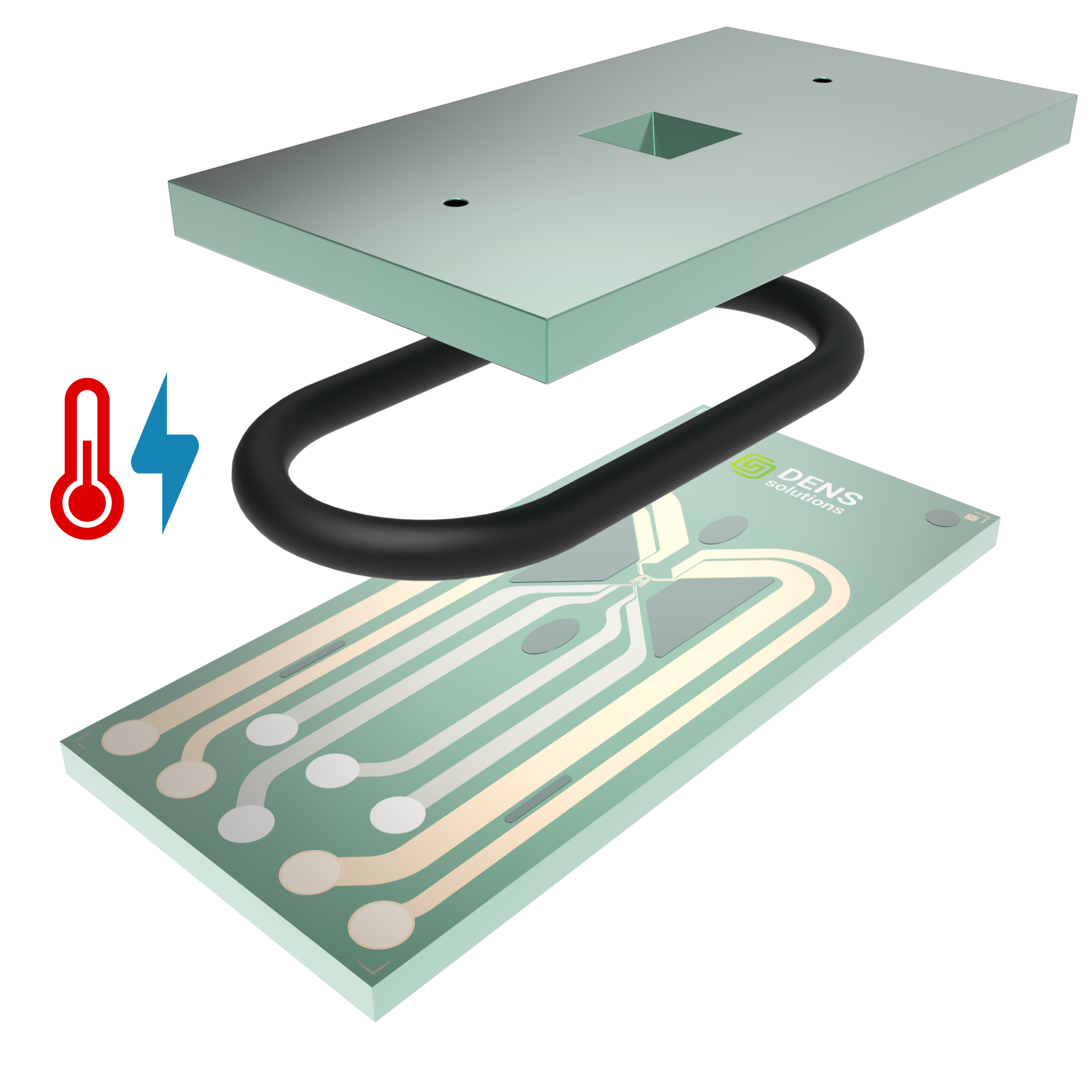

The core of the Climate Infinity system is our patented Nano-Reactor (NR), which consists of a functional and seal chip – together forming a sealed compartment that enables you to safely perform leak-proof gas experiments inside the electron microscope. We offer two different Nano-Reactors that you can select based on your experimental needs: the Gas + Heating NR and the Gas + Heating + Biasing NR.

Gas + Heating Nano-Reactor

Gas + Heating + Biasing Nano-Reactor

Atomic resolution imaging

Observe catalyst dynamics with full S/TEM performance

The Nano-Reactor enables users to achieve real-world gas conditions, such as pressures of up to 2 bar, while imaging at atomic resolution. It is designed to minimize gas thickness at the sample position, limiting interaction with the electron beam. The SiNx windows of the Nano-Reactor, which support S/TEM imaging, have been optimized to withstand the pressure difference between the sample and the TEM vacuum while minimizing electron scattering by reducing the window thickness.

Formation of Cu₂O adlayer on the surface of a copper particle at 750 °C in H₂:O₂ (10:1), revealing an ongoing redox process – By Prof. Marc Willinger (DOI)

Morphological changes observed at 600 °C when a TiO₂ supported Pt particle is exposed to a redox-active atmosphere (700 mbar O₂ and 60 mbar H₂) – By Dr. Hannes Frey and Prof. Marc Willinger (DOI)

Micro-heater

Temperature accuracy, stability & reliability

The Nano-Reactor’s micro-heater is based on the proven and well-established DENSsolutions MEMS technology that offers superior performance in temperature accuracy, reliability and stability. The micro-heater is encapsulated with an inert SiNx protection layer to ensure that the metal of the heater does not interact with the gas or the sample. The contact design of the micro-heater allows for the 4-point-probe method of locally controlling the temperature around the sample being studied. Additionally, the fast feedback control loop swiftly compensates for any local changes in the gas environment around the sample. It adjusts the micro-heater’s power to counteract thermal conductance changes and maintain the target temperature.

Calorimetry

Monitoring heat dissipation & absorption

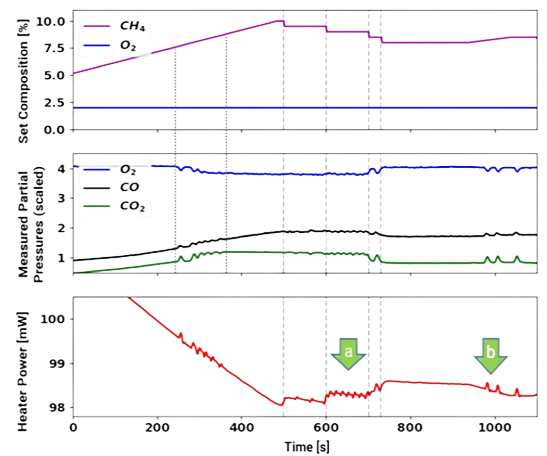

App note – Correlative analysis of methane oxidation catalyzed by palladium

App note – Correlative analysis of methane oxidation catalyzed by palladium

The amount of heat dissipated or absorbed by the specimen during endo- or exo-thermic reactions can be measured with the highest accuracy using the Nano-Reactor’s 4-point-probe micro-heater. Both the resistance across and the power dissipated by the micro-heater are monitored and displayed with ultra-high resolution to observe any changes in sample temperature and/or heat dissipation. In this app note, we demonstrate our advanced heating technology and how it allows not only for accurate temperature control, but also micro-calorimetry and therefore the retrieval of thermodynamic information.

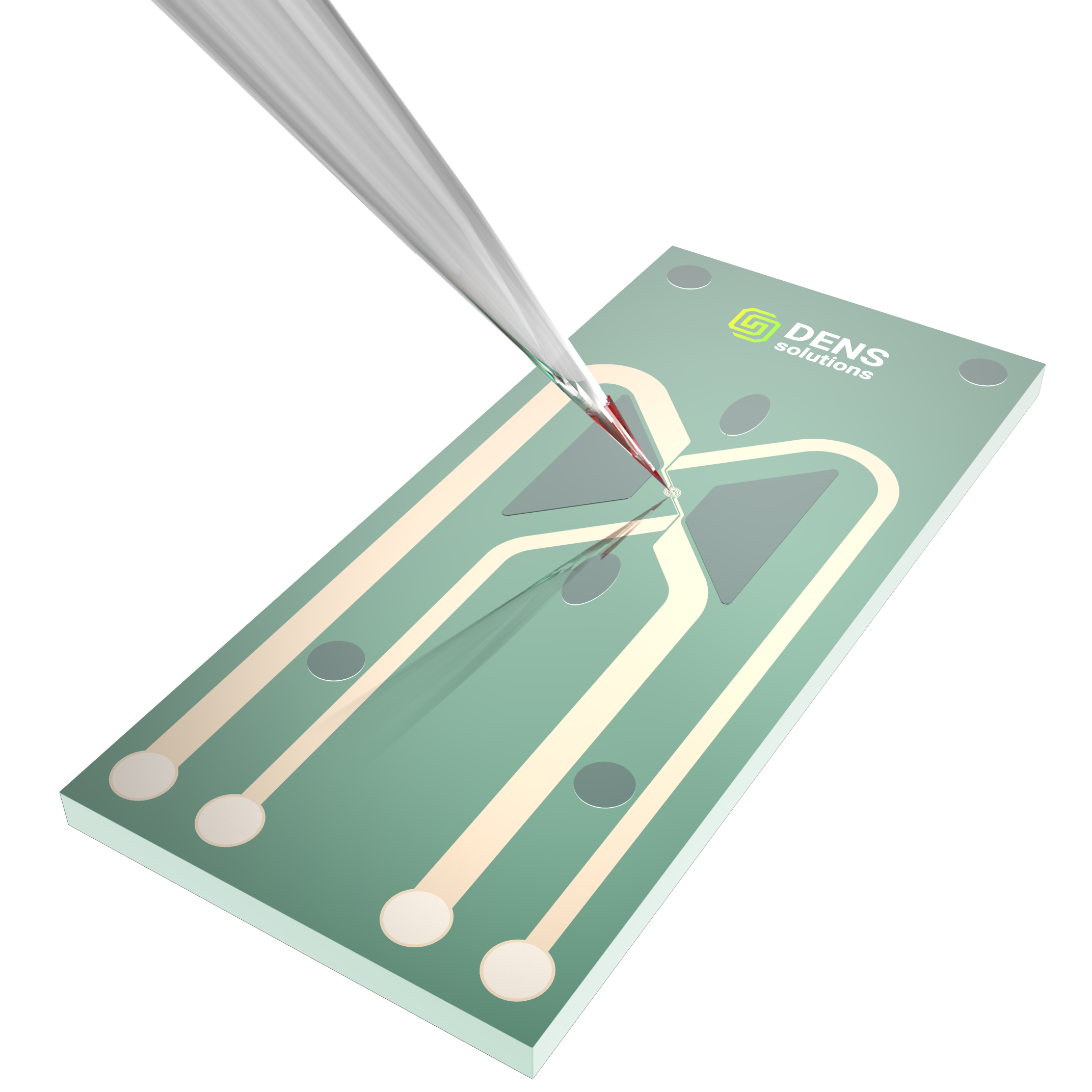

Easy sample preparation

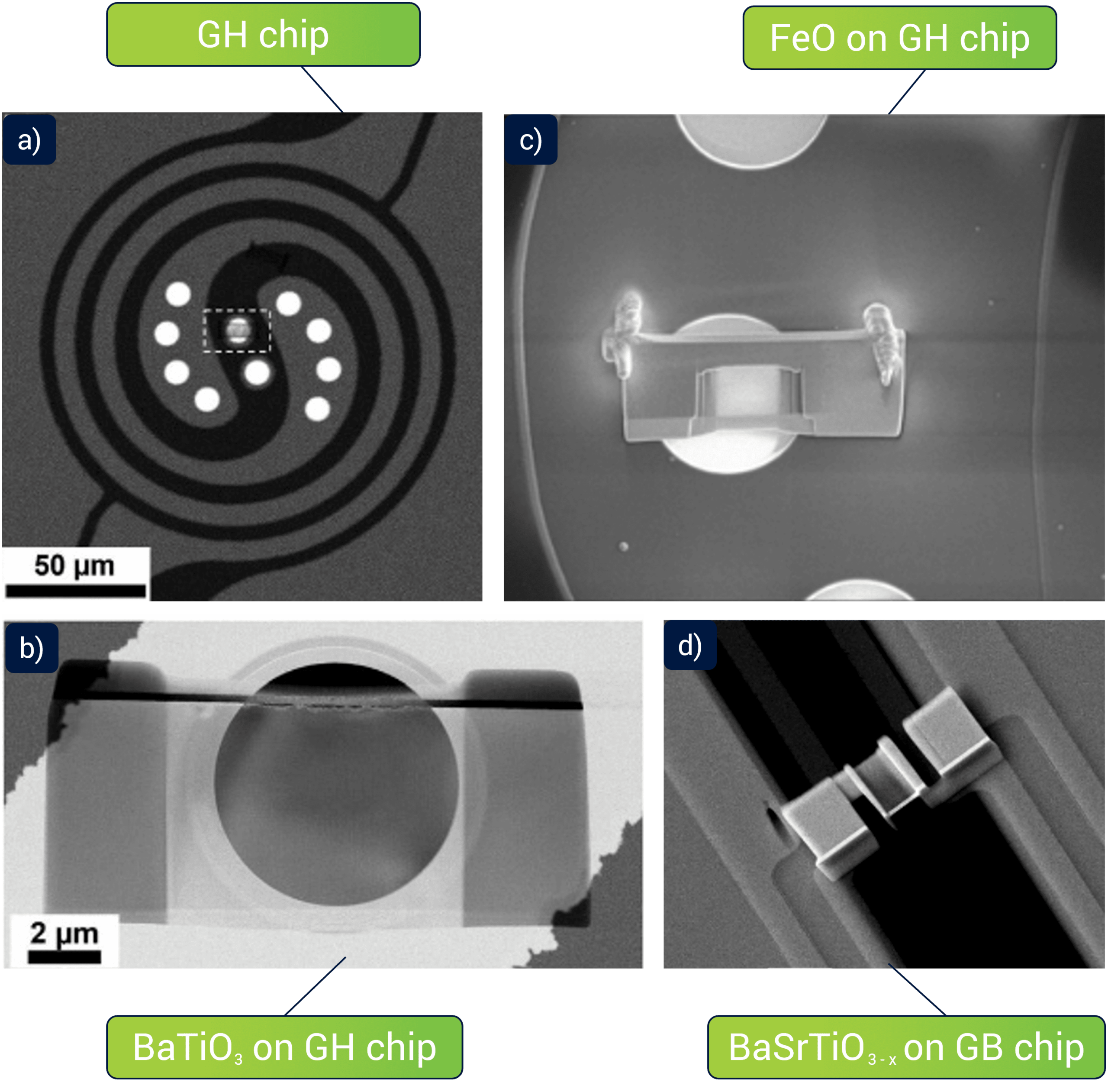

Loading the sample onto the MEMS-based Nano-Reactor is easy and fast to perform. This can typically be done either via a process of dropcasting or via a FIB lamella.

Dropcasting the sample

Nanoparticles are typically in powder form and are prepared in a solvent, such as ethanal or water, for direct dropcasting onto the Nano-Reactor’s electron transparent windows.

FIB lamella

Using a dedicated procedure, it’s also possible to prepare a FIB lamella on the Climate Infinity functional chip in a dual beam either for heating and/or biasing experiments.

a- b) Courtesy of Dr. Miryam Arredondo, QUB; c) Courtesy of Dr. Xuyang Zhou, MPIE Dusseldorf; d) Courtesy of Prof. Dr. Leopoldo Molina Luna, TUD

Request a quote

Request a quotation for any of our products.

Contact us

Get in touch with us for any questions you may have.