Gas Supply System

On-site control of real-world catalyst reaction conditions

The Climate Infinity Gas Supply System is a game changer for in situ TEM catalysis research. It integrates all control functions into one smooth platform. Optimised for the Nano-Reactor, the Gas Supply System controls the gas parameters at the sample location, allowing for imaging and analysis of particles at the atomic scale.

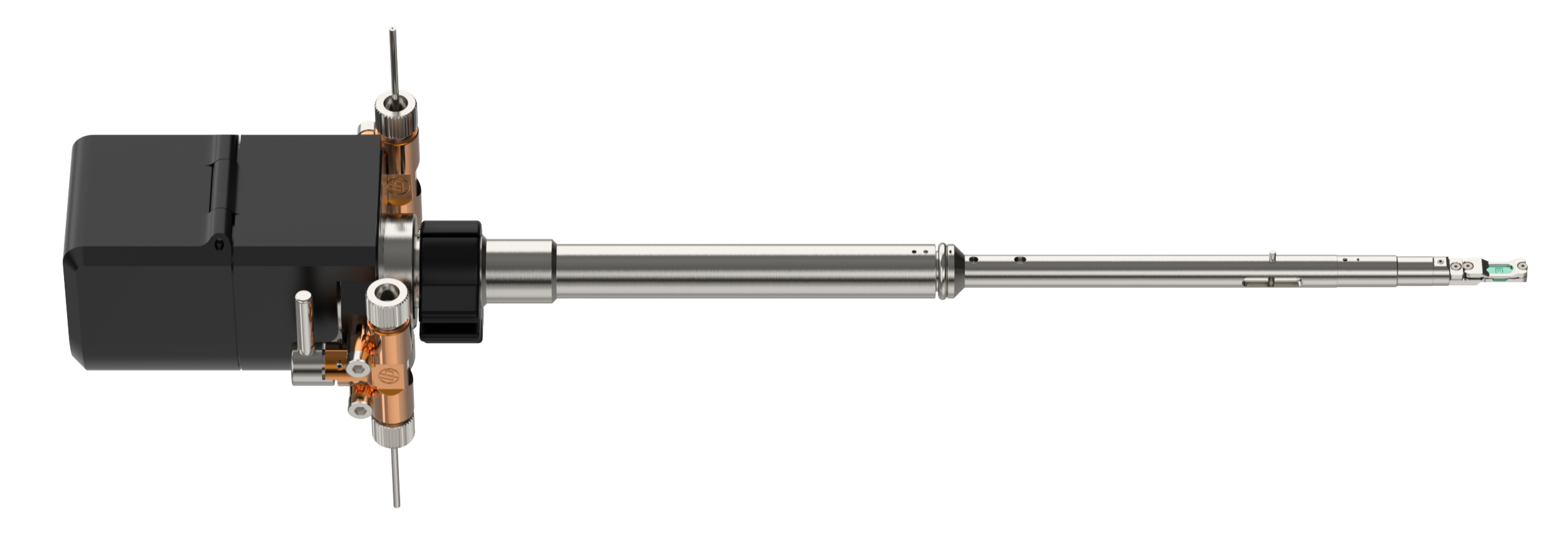

Ultra Fast Flow Control Unit

Changing gas environment takes seconds, not minutes!

The robust and uniquely characteristic Climate G+ swing arm allows for the Gas Supply System to be positioned conveniently within the TEM room. The Flow Control Unit at the end of the swing arm can be maneuvered and adjusted, allowing for the Flow Control Unit to be positioned perfectly behind the Climate Infinity Sample Holder. This allows the Climate G+ user to keep the distance between the pressure controllers inside the Flow Control Unit and the Nano-Reactor as short as possible to enable fast and direct control over gas flow and pressure around the sample. Typically, changing the gas conditions via the Impulse Software results in the sample environment change in less than 15 seconds.

Twin Pressure Controllers

Precise pressure control before and after the sample!

As the Gas Supply System for Climate Infinity has been specifically designed for the Nano-Reactor, twin pressure controllers are mounted in the Flow Control Unit to precisely control the pressure and flow rate into and from the Nano-Reactor (or inlet & outlet to the sample holder). This enables the user to perform experiments with (1) an equal pressure and different flow rates or (2) varying pressures and equal flow rate. Without the outlet pressure controller, a stable back pressure is not possible due to the variables relating to vacuum performance of the pump over time. Therefore, the twin pressure controller setup ensures a reliable flow rate and pressure at the Nano-Reactor.

Patent Protected Mixing Valve

Fast & easy control of the gas composition!

The unique mixing valve of the Gas Supply System provides users with total control of the gas composition without the need for a mixing tank. Changing the gases and/or the composition happens within seconds and directly changes the environment inside the Nano-Reactor that surrounds the sample. Similarly to all components of the Gas Supply System, the mixing value is fully controlled via the Impulse Software and allows for customisation of the workflow to the specific needs of the user/experiment.

Dynamic mixing of up to three gases

The Gas Supply System include three gas lines, allowing the control of pressure and flow inside the Nano-Reactor and the real time dynamic mixing of up to 3 gases. Three gas cylinders of up to 10L can be mounted on the left side of the Mixing Station and connected to the Quick Connect gas inlets. Each gas inlet has a mass flow controller that is calibrated for a specific list of gases. Oxidizing and reducing gases are separated by different inlet lines with the third used for inert gases that can purge the Gas Supply System/Nano-Reactor or dilute reaction gases in an accurate and controlled ratio.

Dynamic mixing of up to three gases

The Gas Supply System include three gas lines, allowing the control of pressure and flow inside the Nano-Reactor and the real time dynamic mixing of up to 3 gases. Three gas cylinders of up to 10L can be mounted on the left side of the Mixing Station and connected to the Quick Connect gas inlets. Each gas inlet has a mass flow controller that is calibrated for a specific list of gases. Oxidizing and reducing gases are separated by different inlet lines with the third used for inert gases that can purge the Gas Supply System/Nano-Reactor or dilute reaction gases in an accurate and controlled ratio.

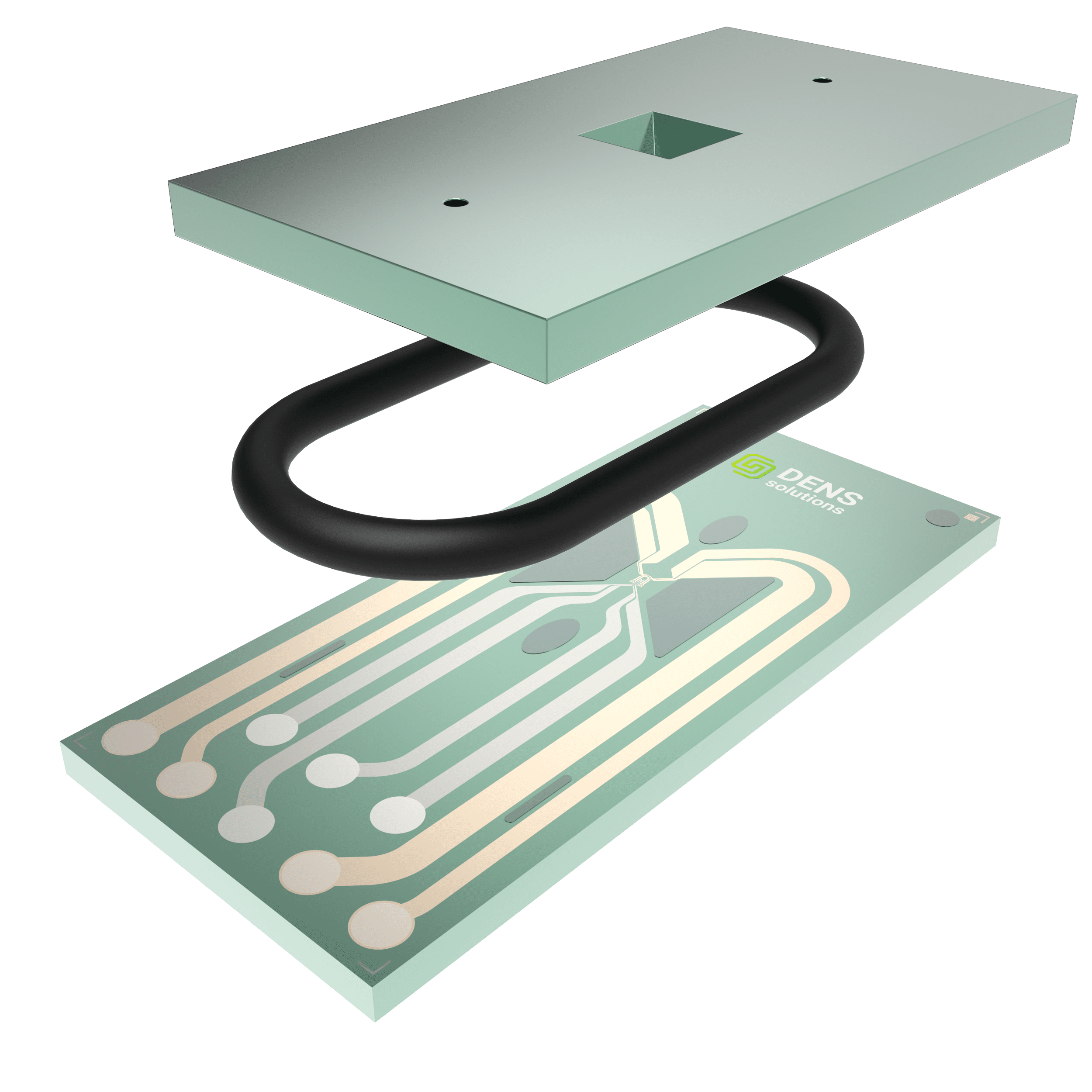

Vacuum Test Tube

Safe & Clean storage of the Sample Holder!

As an integrated feature to the Gas Supply System, a Vacuum Test Tube is used to safely store the Sample Holder in a contamination free vacuum environment. In addition to the safe storage of the Sample Holder, the Vacuum Test Tube also serves as a leak tester following the assembly of the Nano-Reactor. This ensures that any misalignment done during assembly can be quickly identified before inserting the holder into the microscope.

Request a quote

Request a quotation for any of our products.

Contact us

Get in touch with us for any questions you may have.